This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Metallic panels with deep textures

Metallic surfaces were one of the most important trends at this year’s Interzum. These innovative materials caught the attention of visitors with their sophisticated shine, adding luxury and modernity to the furniture on display.

Metallic panels with deep textures offer a combination of modern aesthetics and unparalleled durability. Not only is the metallic look striking, it is also scratch and impact resistant, allowing furniture to retain its lustre for a long time. In addition, the deep structures add three-dimensionality and allow you to create furniture that makes an impact.

Stylistic flexibility should not be forgotten either. Deep-structured metallic panels are versatile – they suit a wide range of styles, from industrial lofts to elegant offices. There is no doubt that this trend will continue to grow in the coming years.

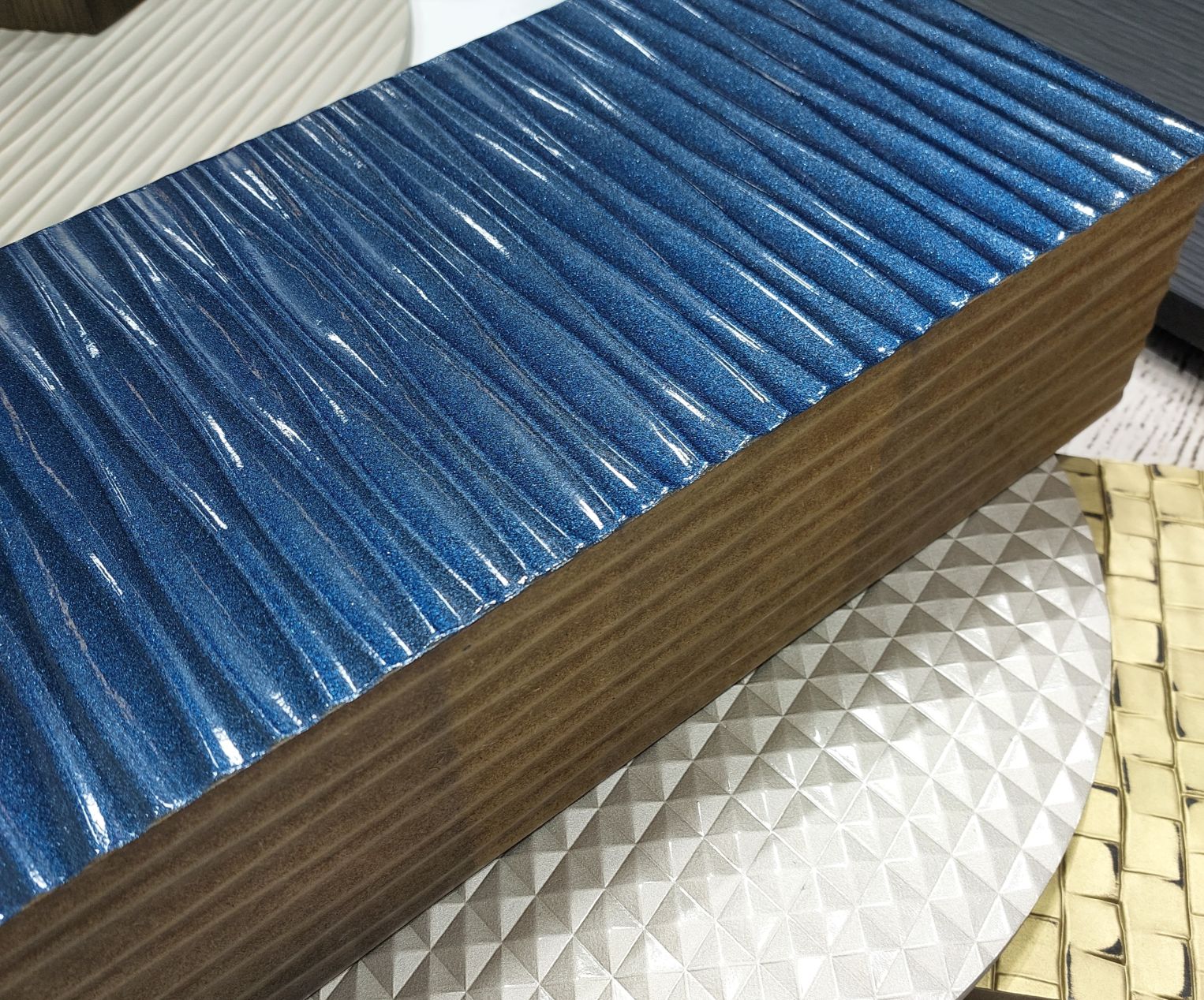

Supermatt collection with metallic effect

Another trend that stole our hearts at Interzum was the collection of supermatt foils with a metallic effect. They respond to the growing interest in materials that combine functionality with a sophisticated look.

They are also extremely versatile. They work well on flat surfaces, adding subtle depth and luxury, but their true potential is revealed on three-dimensional fronts, where they create a unique, dynamic effect.

Importantly, these films are available from Melaco in our Star Dust collection. They have been created for the most demanding projects where both aesthetics and durability are important. This trend is a true combination of beauty and functionality that we are sure to see in more and more modern interiors.

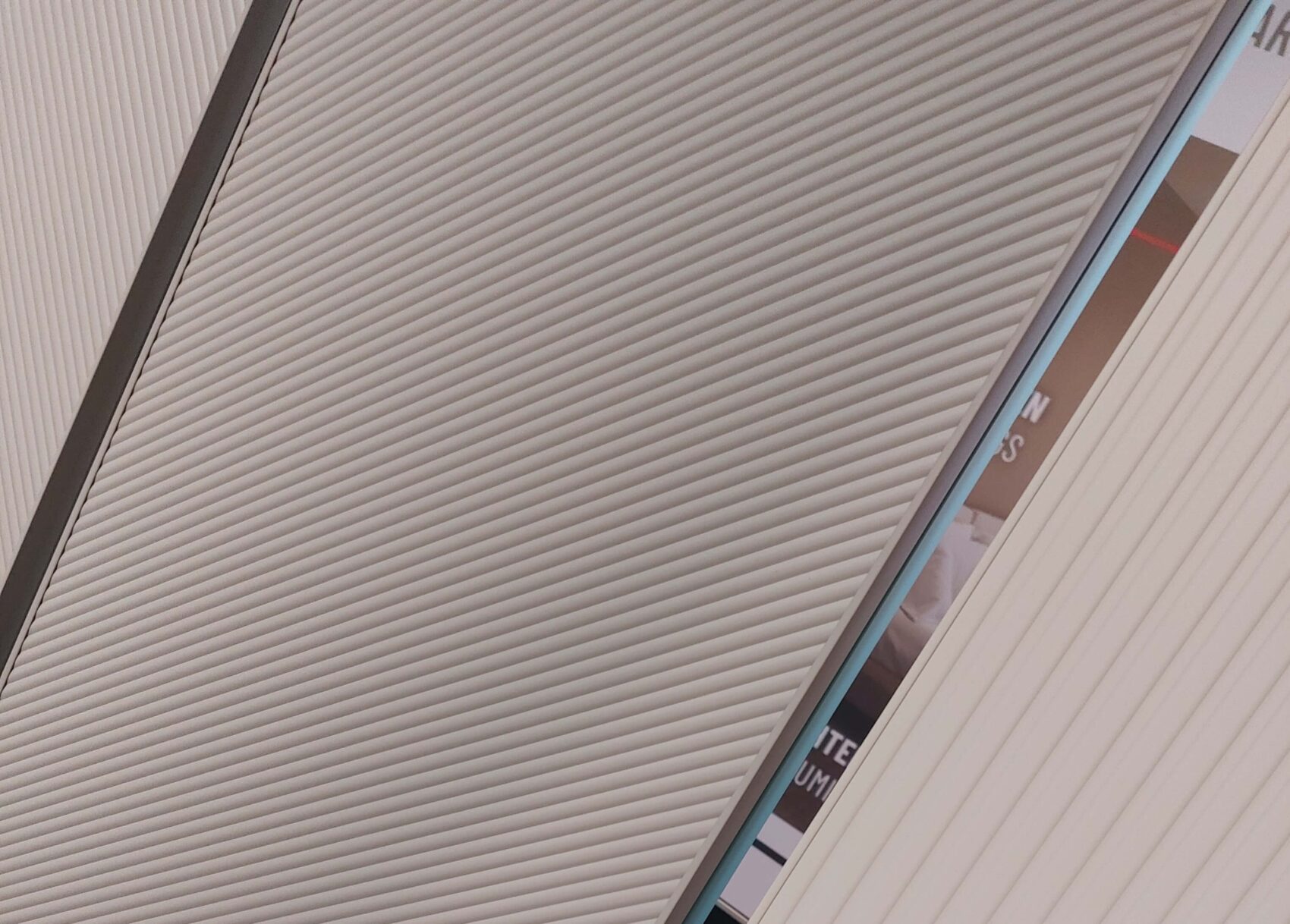

Micro Milling™ – precision and aesthetics in one

Visitors’ eyes were drawn to Micro Milling™ technology. This innovative approach to processing the surface of a panel brings new quality and precision to the world of furniture design.

Micro Milling™ technology, presented by our long-time partner Renolit, consists of milling the outer layer of a board covered with a two-ply single foil, a two-ply foil or natural veneer in various patterns and colours. Using diamond cutters and advanced copying units with real-time electronic thickness measurement, we are able to achieve unprecedented accuracy and exceptional visual effects.

Also read: Colour Road 2023/24. RENOLIT sets off on another trend journey →

Micro Milling™ technology is available to our customers in a wide range of colours. This is another step towards creating unique, customised solutions that meet the expectations of even the most demanding customers. Micro Milling™ is definitely a trend that will redefine the boundaries of what is possible in the furniture industry.

Geometric surface textures – bold in form

A trend that we have seen grow in popularity in recent months is geometric surface textures created using CNC milling technology.

The variety of patterns on show at the show was impressive – from vertical, horizontal and diagonal lines to delicate waves and sophisticated convex diamonds. Each pattern created a unique, three-dimensional structure that added depth and character to the surfaces.

Geometric surface textures are ideal for those looking for unique solutions to transform their space into a true work of art. Introducing this technology into an interior is a way to create an individual and unique atmosphere. There is no doubt that geometric textures will continue to triumph in the world of design.

Also read: Our inspirations: Furniture collections with milling cutters and carvings →

Digital printing – nature meets technology

Digital printing, one of the most exciting trends to be seen at Interzum, opens up new possibilities for lovers of unusual design. It allows the creation of unique, subtle designs that would not be possible with traditional techniques.

At the fair, we particularly noticed designs that combined natural wood patterns in different shades with marine colours and black. These exotic compositions bring a touch of the wild into the interior while creating an extremely elegant effect.

It is a technology that allows us to create almost any pattern, opening the door to a world where the only limit is our imagination. There is no doubt that this trend will have a significant impact on the future of interior design.

Threespine® ID – Innovation in furniture assembly

An interesting technological solution was presented by our partner and licensor, Vallinge Innovations AB. Threespine® ID is a tool-free system for assembling furniture components using wooden dowels and eccentric elements made of Shuko plastic to block and stabilise the back panel. This method not only streamlines the assembly process, but also ensures durability and an aesthetically pleasing finish – the dowels and connectors are invisible to the eye.

This innovative approach to furniture assembly is a real game changer in the furniture industry. Threespine® ID offers a significant streamlining of the assembly process, which is not only convenient, but also translates into the longevity and aesthetics of the finished products. This is definitely a trend to watch in the coming years.

Natural patterns – timeless elegance

An enduring trend that has been seen at various trade shows and in orders for many years is enjoying unbroken popularity. These are natural, wood-like designs with a calm, even grain, as well as designs that imitate textiles and stone.

These patterns, which draw on natural colour palettes and textures, add a sense of calm and elegance to a room, whatever the style of interior chosen. It is a way of bringing an atmosphere of harmony and comfort into the home, reminding us of our closeness to nature.

Also read: Melaco at Meble Polska 2023. Trends in furniture industry →

At Melaco we are aware of the sustainability of this trend. We have adapted our range of foils so that we can offer fronts and furniture with a similar natural finish. This proves that classics and naturalness never go out of fashion, on the contrary, they are a solid foundation for any modern design.

Ecology – the future of furniture manufacturing

A dominant trend that can be seen at all trade fairs, and not just in the furniture industry, is undoubtedly ecology – especially the use of fully recycled materials. This is the direction in which manufacturers all over the world are constantly moving, looking for new, more sustainable solutions.

At Melaco, we are determined to keep up with this trend and want to implement it in our own production. Based on an agreement with RENOLIT, our renowned supplier of PP, PVC and PET films, we aim to use recycled waste raw materials in our production from 2021.

We also ensure that PVC, PP and PET film waste is not sent to landfill but is processed. We send it to a certified recipient who recycles it and supplies it to manufacturers of other products. To do this, we use a baler to bale the film waste, which reduces its volume as much as possible and makes collection more cost-effective.

The environmental trend is definitely the direction in which the entire furniture industry should be moving. At Melaco we are proud to be part of this positive change.

Interzum 2023 – an important glimpse into the industry’s future

As always, attending Interzum was an extremely valuable experience for us and an invaluable source of inspiration. We learned about the latest trends and technologies in the furniture industry. We have also had days full of meetings with our partners and customers. These are always very enjoyable and beneficial.

We are delighted to have had the opportunity to participate in this unique event and look forward to the next editions. Thank you for reading our article. We hope that we were able to convey at least some of the emotions and impressions we experienced during this event. See you at the next Interzum!

Contact

Do you have questions? Contact us.

We will be pleased to answer all questions about MELACO’s offer, terms of cooperation and orders. Write or call us.

Contact

Melaco sp. z o.o.

ul. Ciepielowska 9

67-100 Nowa Sól

Poland

SALES DEPARTMENT

Agata Sroczyńska

Sales Coordinator

SALES DEPARTMENT

Beata Prałat

Sales Specialist