This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Individual approach to each customer

Despite the fact that we have a professional machinery park and a team of experienced specialists, we are not limited to working only with the largest players in the market. We serve both large furniture manufacturers and beginners who are taking their first steps in the industry. We do not require a ready-made technical design, as we are able to design specific components even on the basis of a conversation with the customer or determining the style of the target furniture.

Most often, cooperation begins with an inquiry. The customer can send us ready-made technical drawings or even a photo from the phone with inspiration, and we take care of the rest. Our technologist develops solutions that are functional and optimize production costs, explains Agata Sroczyńska, Sales Coordinator at Melaco.

You don’t have to be a professional to work with us. Even if the client doesn’t have technologists on his side, we are able to help at every stage – from the design to the finished product, adds Jakub Zieliński, our Production Specialist.

At Melaco, we also focus on effective cooperation with customers through material consulting. We help customers select the ideal components that not only meet their aesthetic expectations, but also optimize production costs.

Often customers ask about matching the colors of the film to particleboard or MDF. Thanks to cooperation with reputable suppliers, we can offer perfectly matched components, which saves both time and costs, explains Agata Sroczyńska.

Melaco’s modern technologies

We use the latest technologies, such as vacuum pressing and HOT MELT LAMINATION. But that’s not all – we are constantly looking for new solutions and testing innovative materials. Recently, we created a front based on a client’s visualization, which turned out to be a real hit. It was something completely new and we are happy that we were able to realize it, recalls Agata Sroczyńska.

Agata Sroczyńska, Sales Coordinator at Melaco

The most important of our technologies are:

• HOT MELT LAMINATION

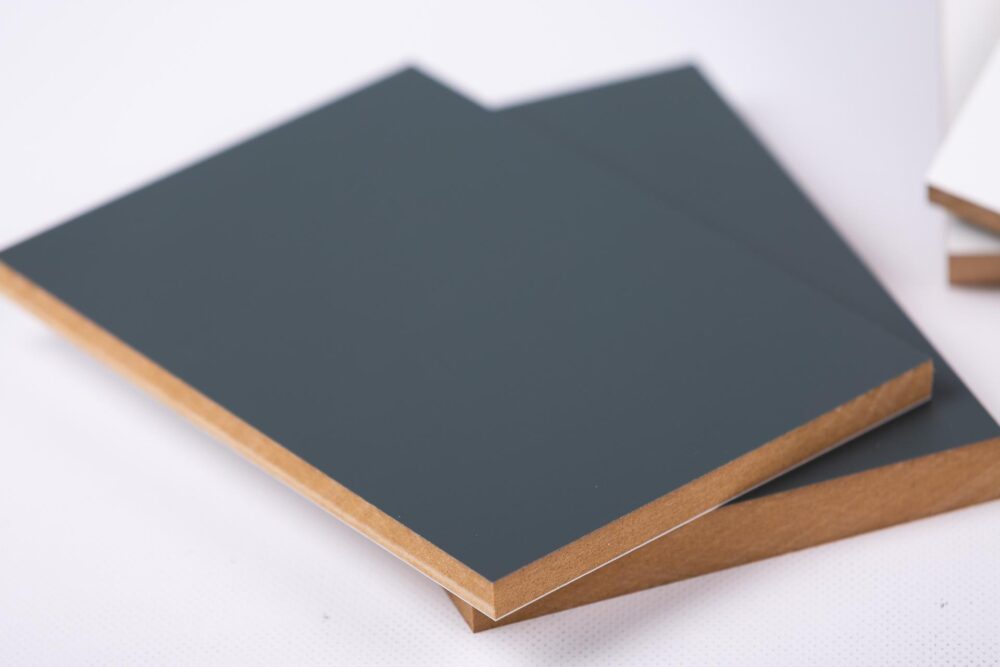

Hot lamination technology using PUR (polyurethane) adhesives, which provides exceptional durability and resistance to mechanical damage, moisture and high temperatures. Thanks to this method, we create components with a smooth surface, which are ideal for the production of kitchen, bathroom, bedroom or office furniture. In addition, the use of film with anti-fingerprint properties in components with PREMIER MATT finish allows us to achieve an aesthetic finish without visible fingerprints.

→ Read more about HOT MELT LAMINATION here.

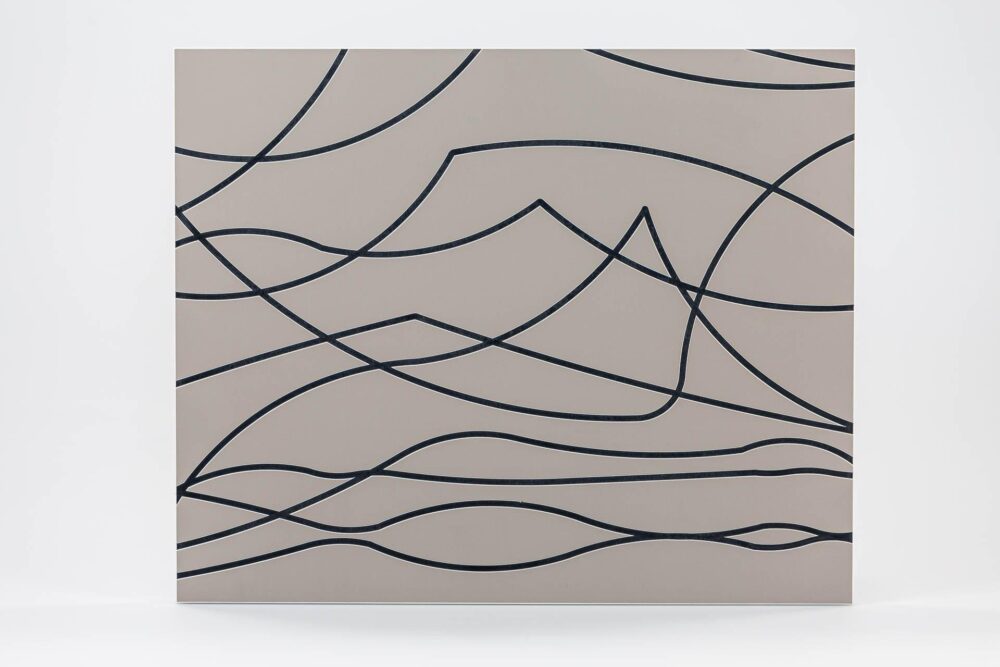

• MICRO MILLING™

This is an innovative technology for precision surface treatment of furniture boards. It involves milling the top layer of the material, which allows the creation of unique patterns and structures – from minimalist lines to intricate ornaments. MICRO MILLING™ opens up new possibilities for designers, making it possible to personalize furniture and give it unique designs. It’s a solution especially appreciated in premium projects.

It allows us to create unique patterns on furniture surfaces, which opens up new possibilities for designers and manufacturers, underlines Jakub Zielinski.

• MELAFOL

The MELAFOL production line specializes in creating 3D furniture fronts with deep milling, which give furniture a three-dimensional effect. Thanks to this technology, it is possible to obtain both subtle Scandinavian-style designs and more expressive forms with a classic character. MELAFOL fronts are resistant to moisture, scratches and high temperatures, making them an ideal choice for a variety of applications – from kitchens to living rooms.

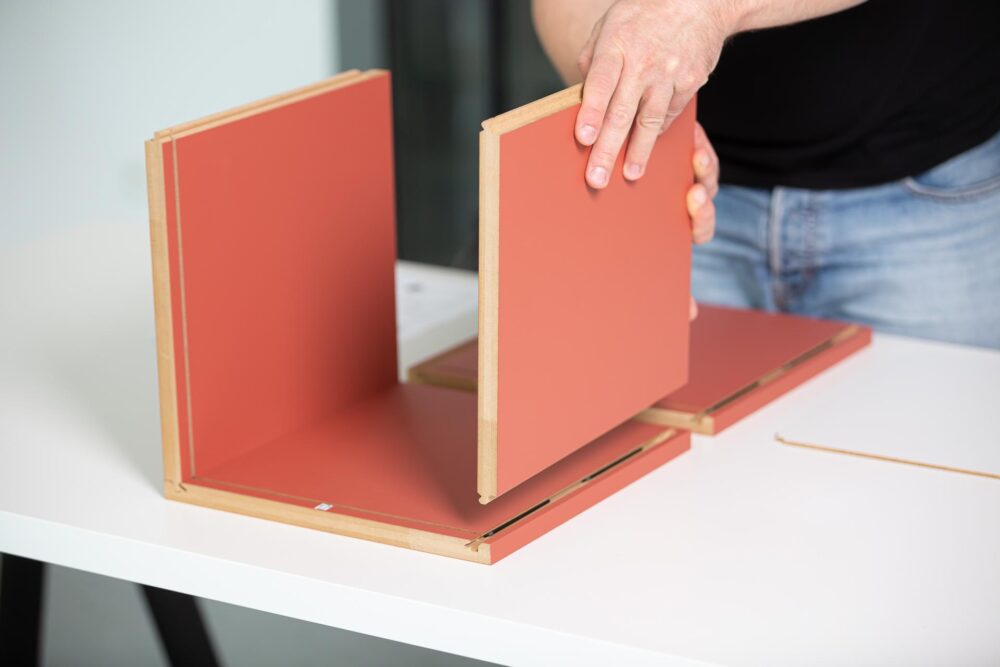

• Flick&Click™

The Flick&Click™ system, licensed from VALINGE INNOVATION AB, is based on Threespine® tool-free assembly technology, enabling fast and tool-free assembly of furniture. This solution is particularly useful in modular systems. Flick&Click™ allows for easy adjustment of components while guaranteeing the stability and aesthetics of the finished product.

“Challenges help us grow”

Melaco employees agree that custom projects are the most rewarding. We love to realize complex orders. This develops our company and allows us to build a portfolio of innovative solutions, the production employees say.

An example of this approach was one of the front designs from the MELAFOL line. The customer sent a photo of the front, which looked like it was made of MDF dyed in the mass. We proposed an alternative solution with our technology and the effect was excellent, says Agata Sroczyńska.

Another successful collaboration wasA partner, not just a supplier! the delivery of our innovative roll elements, which were used in the design of a console with curved sides. The furniture was presented at the Meble Polska 2025 trade fair by our long-time customer Meblosiek.

A partner, not just a supplier!

Melaco is more than a manufacturer of furniture components – it is a technology partner that supports its customers in realizing their visions. We understand well that every project is different and requires an individual approach.

We have the most fun creating something new and unique. These are the projects that show our capabilities and inspire us to further develop, underlined Melaco employees.

Get in touch with us and see for yourself how professional our approach to customer cooperation turns out to be!

Contact

Do you have questions? Contact us.

We will be pleased to answer all questions about MELACO’s offer, terms of cooperation and orders. Write or call us.

Contact

Melaco sp. z o.o.

ul. Ciepielowska 9

67-100 Nowa Sól

Poland

SALES DEPARTMENT

Agata Sroczyńska

Sales Coordinator

SALES DEPARTMENT

Beata Prałat

Sales Specialist