This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Market trends driving demand

The year 2024 has brought significant changes in consumer preferences. Customers have increasingly sought personalized furniture that allows them to express their individual style. There has also been a growing interest in three-dimensional textures and expressive patterns that add character and depth to interiors. As Beata Piotrowska, Deputy Director of Production and Development at Melaco, points out, current trends emphasize above all design diversity, personalization and innovative production technologies.

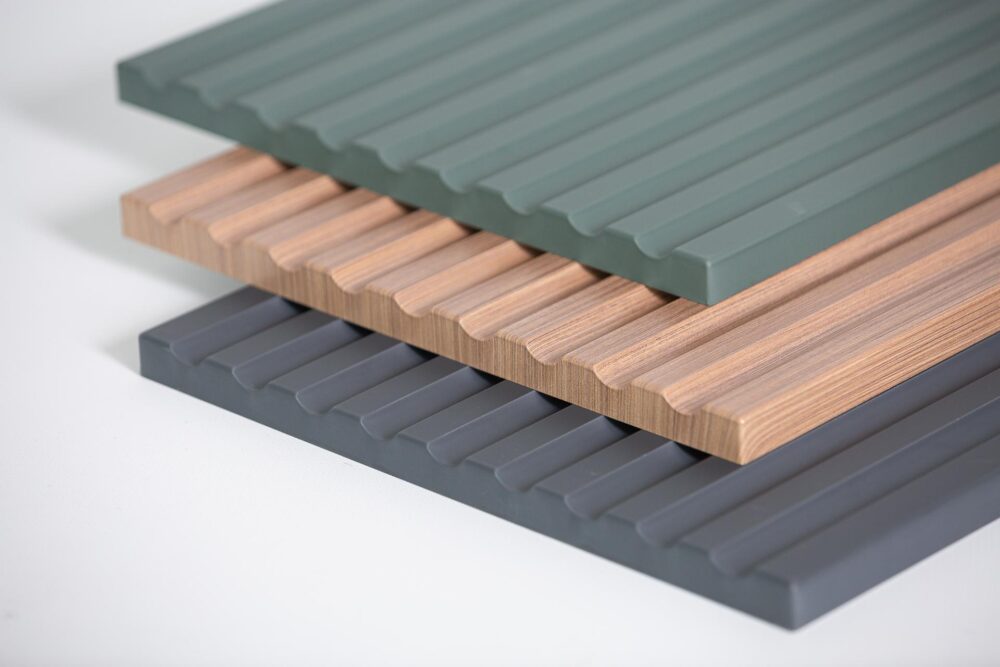

MELAFOL fronts 1. Wave + Kalcyt | White PREMIER MATT 2. Woody 1041

Technological advantages of the MELAFOL line

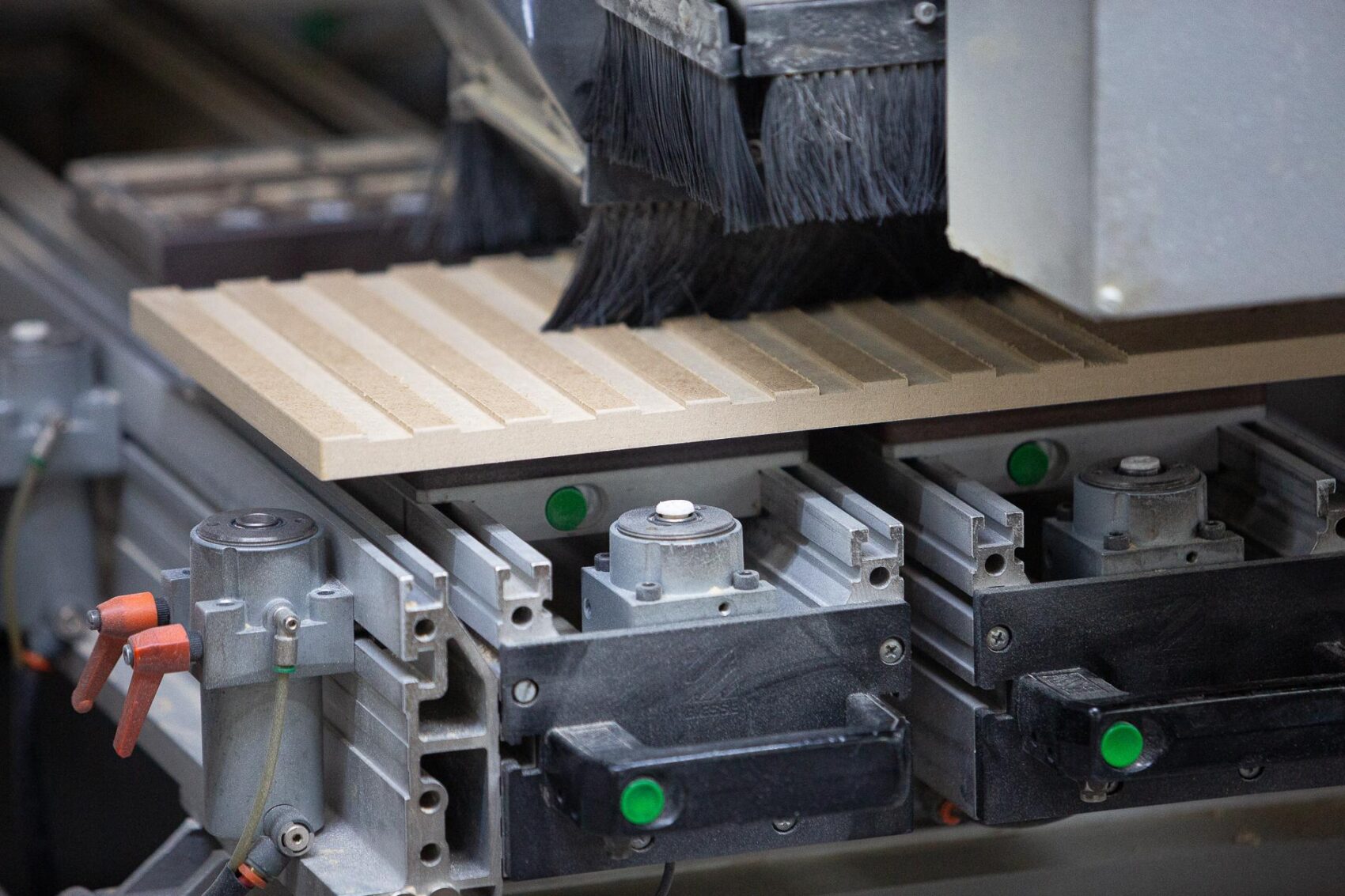

MELAFOL fronts are manufactured using advanced technologies such as CNC milling and vacuum pressing, which guarantees high precision and durability of the products. The base for these fronts are one-sided laminated MDF boards with a thickness of 16-25 mm, which are covered with high-quality polymer films supplied by renowned European manufacturers. The vacuum pressing process ensures perfect adhesion of the film to the surface, which translates into an aesthetic finish and resistance to daily use.

Melaco has a state-of-the-art machine park, enabling it to carry out a variety of projects, from minimalist to more complex geometric patterns. CNC technology makes it possible to precisely mill unique structures, such as laths or irregular geometric patterns. Production is carried out in accordance with the principles of sustainable development – all materials meet strict formaldehyde emission standards and are FSC® certified, which confirms their ecological origin.

Thanks to such advanced technological facilities, Melaco is able to fulfill orders in a “make to order” (MTO) system, tailoring each product to B2B customer specifications. Investment in innovative technological solutions not only improves product quality, but also enables optimization of production costs and reduction of waste, in line with the company’s sustainable development strategy.

Unlimited design possibilities

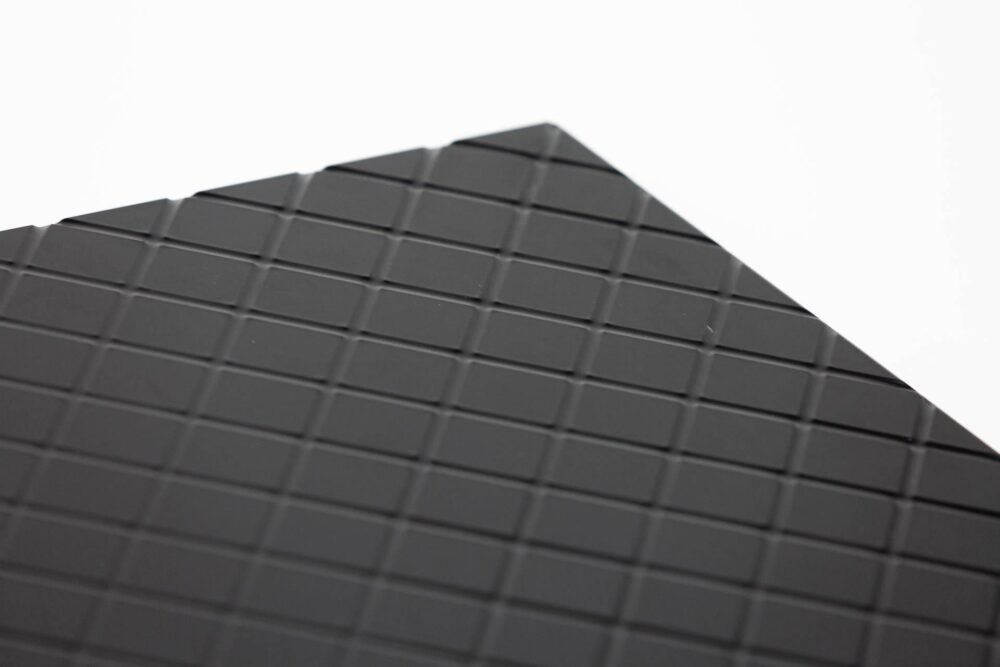

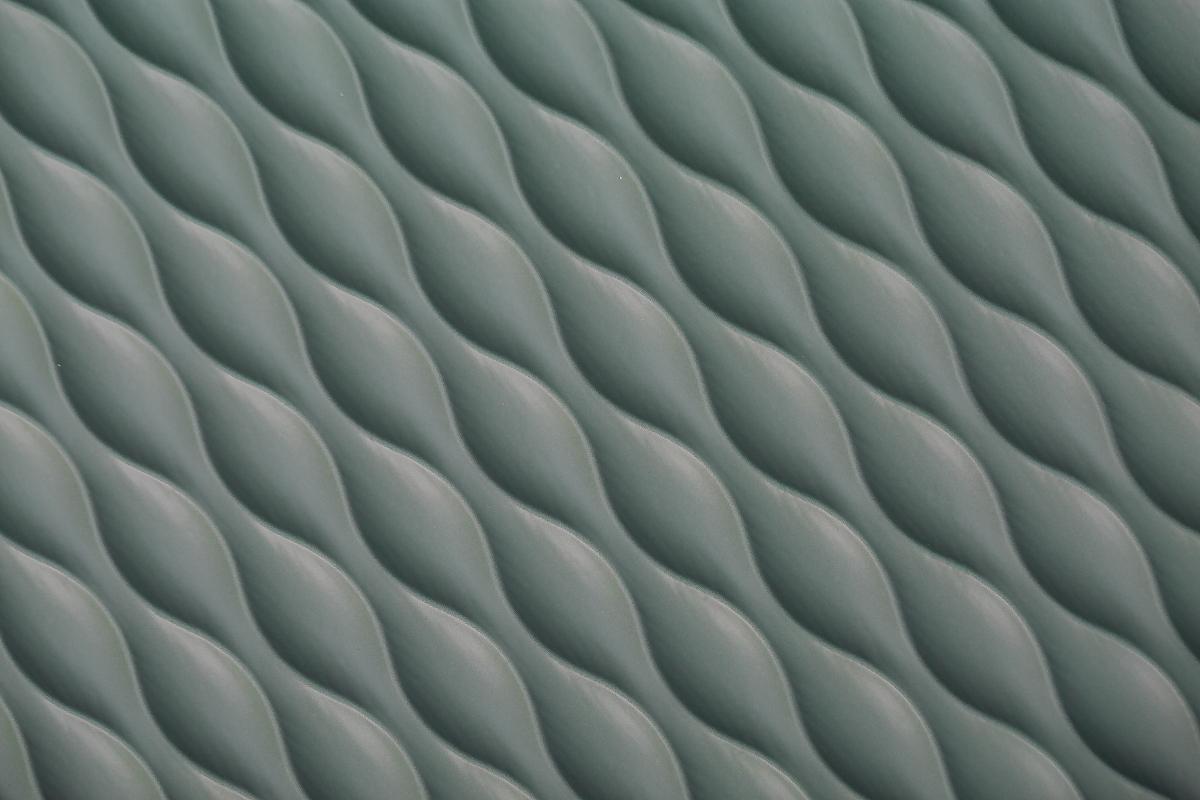

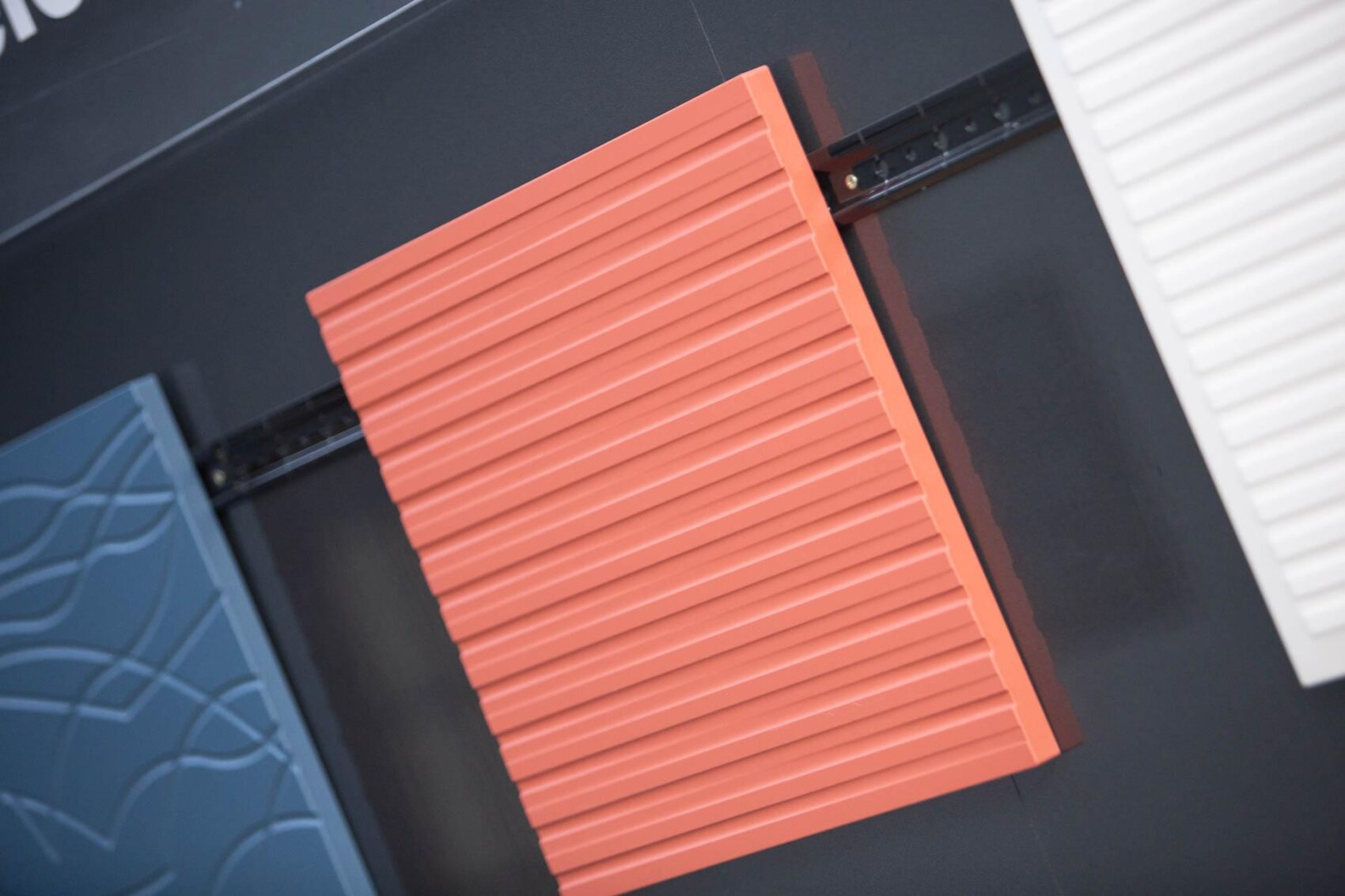

MELAFOL fronts offer furniture manufacturers almost unlimited design and personalization possibilities. Customers can choose from a wide range of designs – from minimalist lines and subtle embellishments to more complex ornaments or 3D structures, such as geometric reliefs, wavy lines or honeycomb textures.

An example of a 3D pattern produced within the MELAFOL line

In addition, a wide range of colors and finishes – from Premier Matt super-matte surfaces with anti-fingerprint effect to metallic accents – makes it possible to adapt the fronts to different interior styles, from modern to classic. This allows designers and manufacturers to create furniture that perfectly matches current market trends and individual customer needs.

MELAFOL fronts 1. Design on request | Frez romb 286 2. Roof Flow | Cashmere PREMIER MATT

Business benefits for manufacturers

Reduction of complaints

One of the key advantages of MELAFOL fronts is their exceptional durability and resistance to daily use. Thanks to the use of high-quality MDF boards and polymer films, these fronts are resistant to moisture, elevated temperatures and scratches. Supervised vacuum pressing technology and the highest quality two-component PUR dispersion adhesives used ensure high heat resistance, which minimizes the risk of complaints. For manufacturers, this means saving time and costs for after-sales service and building a positive brand image.

Increase competitiveness

MELAFOL fronts allow manufacturers to stand out in the market through innovative design and high quality workmanship. The ability to create unique designs while keeping production costs affordable gives a competitive advantage, especially in the premium furniture segment. In addition, extensive customization options allow manufacturers to respond to growing customer demand for customized furniture.

Sustainability as an added value

Melaco consistently pursues a sustainable development strategy, which is reflected in its production processes and products offered. MELAFOL fronts are manufactured from certified wood-based panels (FSC®), which guarantees responsible management of forest resources. In some projects, the company also uses the innovative FLORA film – a biobased PVC material made from natural ingredients such as salt and pine oil. FLORA film reduces CO2 emissions by up to 90% compared to traditional PVC, making it more environmentally friendly.

In addition, Melaco implements RPET films, which are based on PET recyclate. By using an innovative mechanical and chemical recycling process, the resulting raw material is stable and homogeneous, just like pure PET pellets. RPET films are used in the production of furniture fronts, offering durability and aesthetics while minimizing environmental impact. Their use reduces the amount of plastic waste and fits in with the idea of a closed loop economy. In addition, Melaco implements procedures for recycling materials that can be reused by furniture manufacturers. This kind of approach not only reduces the carbon footprint, but also fits in with the EU’s climate neutrality goals.

Versatile application

MELAFOL fronts are widely used in various segments of the furniture market. Thanks to their durability and resistance, they can be used in room and bedroom furniture, as well as kitchen or bathroom furniture – even in demanding conditions of increased humidity and temperature. They are also perfect for the production of office and modular furniture.

Thanks to the flexibility of its manufacturing technology, Melaco offers customized solutions to meet the various needs of B2B customers – from ready-made formats to custom-made components. The versatility of MELAFOL fronts allows manufacturers to effectively use the technology in a wide range of projects, making it an ideal choice for companies operating in both mass and premium markets.

If you want to increase the competitiveness of your furniture offerings and deliver the highest quality customized products, contact us today! We offer comprehensive solutions aimed at B2B customers. Join the leaders of the furniture industry and discover the potential of cooperation with Melaco!

Contact

Do you have questions? Contact us.

We will be pleased to answer all questions about MELACO’s offer, terms of cooperation and orders. Write or call us.

Contact

Melaco sp. z o.o.

ul. Ciepielowska 9

67-100 Nowa Sól

Poland

SALES DEPARTMENT

Agata Sroczyńska

Sales Coordinator

SALES DEPARTMENT

Beata Prałat

Sales Specialist