This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Kitchen furniture fronts from sustainable forestry

At MELACO, we place great emphasis on the quality of our products, and this starts with the selection of materials. We make sure that all the boards we work on come from proven sources and ensure not only quality but also do not contribute to deforestation. Therefore, until 2014, we have the FSC® certificate, which confirms that the raw material used in production comes from a certified supply chain, and we, as a company, follow the good practices specified in the FSC® requirements.

What does this mean for producers of kitchen furniture fronts?

By choosing products with this label, you show that you care about the environment. You limit the degradation of forest resources, protect endangered species from extinction and reduce the negative impact of human activities on climate change. The FSC® certificate also increases the company’s credibility and inspires trust among conscious customers. This is a measurable benefit for producers who care about a positive image and running a responsible business.

Our care for the natural environment, as well as high product quality and an innovative approach to creating furniture collections, ensured us an award in the prestigious FSC Furniture Awards in 2021. Our HOME OFFICE Select product line, which won the international competition, is also the first Polish collection to be awarded this title.

You can read more about the award and this furniture collection here: Melaco with the FSC Furniture Award 2021!

Quality in line with standards

Kitchen furniture fronts must also meet the appropriate standards, which will ensure the right functionality in such a demanding room as the kitchen. All our fronts are made of durable MDF with a reduced formaldehyde content and meet the stringent DIN EN 16516 standards. On one side, they are covered with a polymer film from proven and well-known suppliers with a selected pattern, and on the other side – with a laminate. The process of glueing MDF boards is performed with the use of durable PUR dispersion adhesive, which gives the fronts high resistance to moisture and elevated temperatures up to 70ºC.

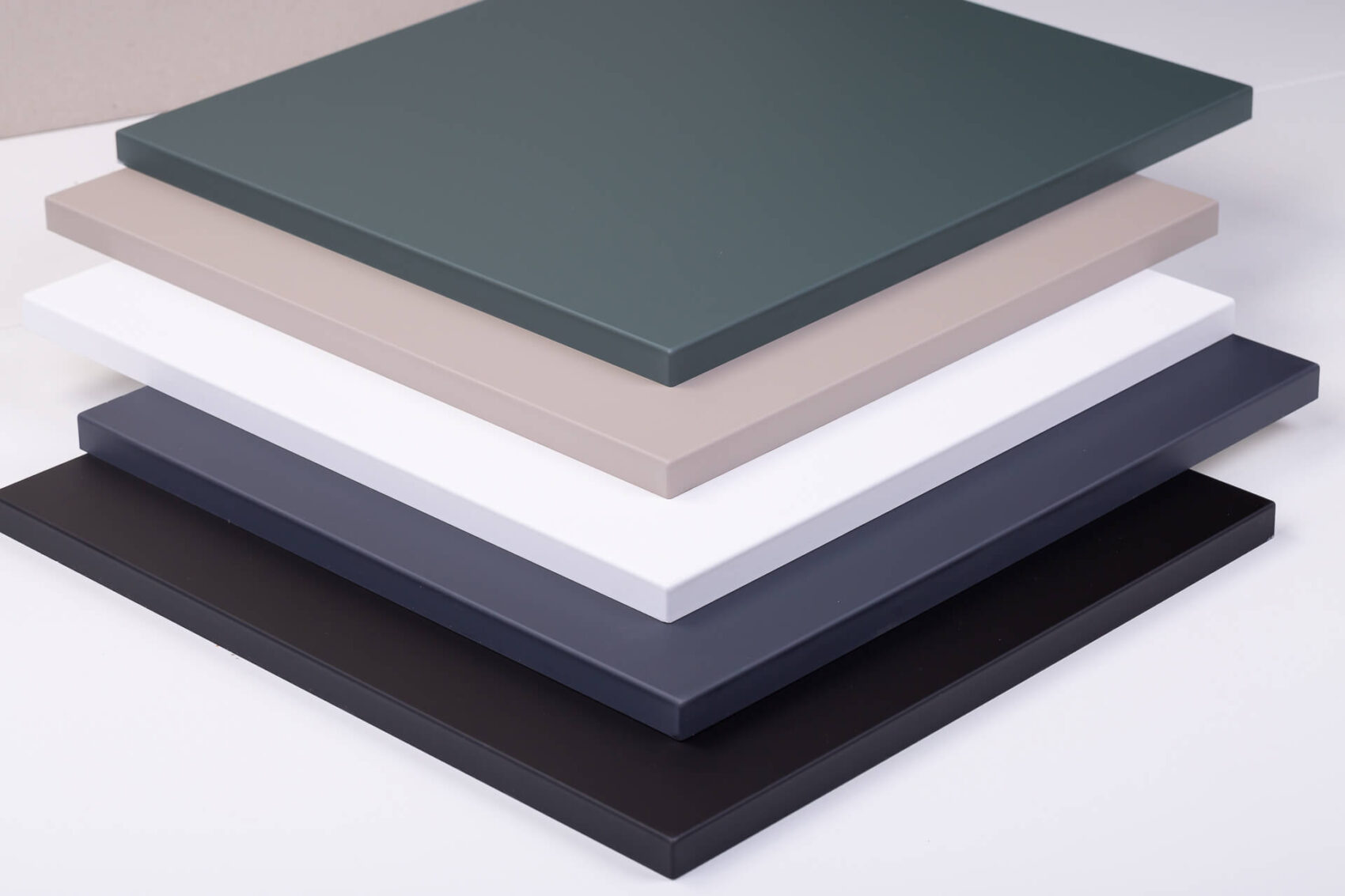

COMPLETE SKIN furniture boards and ribbons, which we use in the production of fronts, are available in a wide range of colours. They allow you to create any collection and arrangement. In addition, we offer our business partners an attractive COMPLETE SKIN EXPRESS program, under which all standard patterns are available within 14 days!

Kitchen furniture fronts: glossy or mat?

Gloss or mat – this is the first question that consumers who arrange their kitchens ask themselves. Therefore, both of these types of finishes must be a standard in every offer of kitchen furniture fronts. At MELACO, we offer manufacturers a mat, super mat and gloss finish, but for demanding partners we have something special: MAGIC GLOSS and PREMIER MATT. Why are they unique?

MAGIC GLOSS offers the effect of high-gloss kitchen furniture fronts, which impress with their perfect surface and practical parameters. They are created on the basis of vacuum pressing technology – during this process, the MDF board is covered with PVC or PET foil protected with a protective foil. As standard, the left side is finished with a melamine layer. MAGIC GLOSS furniture fronts are resistant to moisture, stains and UV rays. They do not discolour over time, and keeping them clean is extremely easy. All this means that furniture fronts made in this technology will please the household members for many years.

PREMIER MATT is a deep matt effect with a low light reflectance (2⁰-3º). Kitchen furniture fronts covered with this foil offer not only an extremely matt structure but also many benefits related to their use:

- Resistant to stains (1B) and scratches (1.1-5 N).

- The ability to regenerate under the influence of heat (thermal healing) – just gently heat the surface of the foil and all small scratches will disappear.

- Anti-fingerprint effect – no fingerprints are left on its surface.

The magnificent final effect provided by the MAGIC GLOSS and PREMIER MATT finishes, combined with their durability and ease of cleaning, will make consumers enjoy them for years to come.

Milled furniture fronts for the kitchen

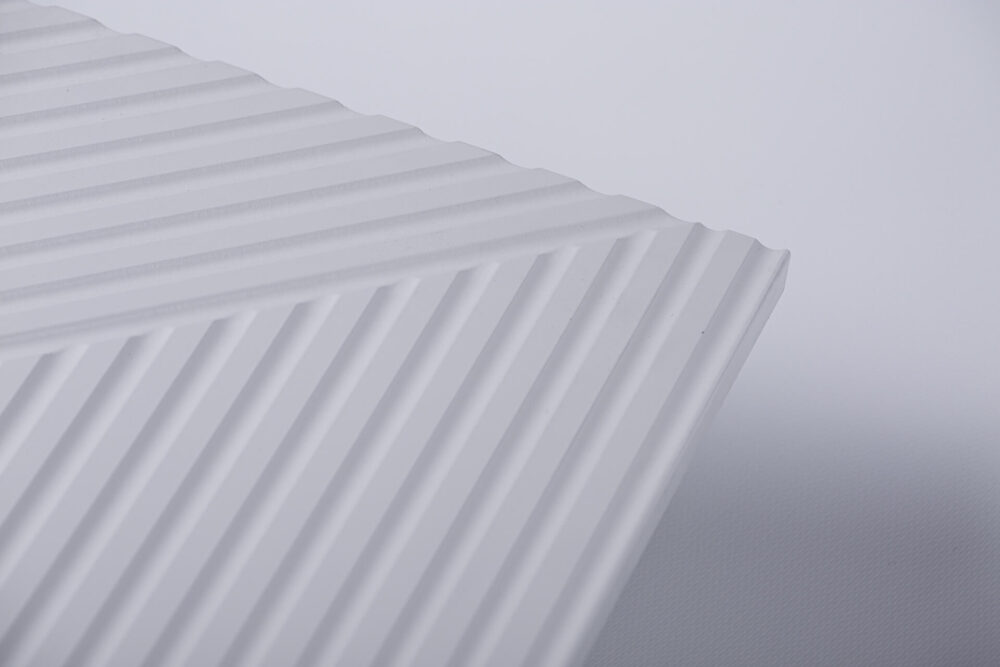

Furniture fronts with a smooth structure are the finishing elements most often chosen in modern, minimalist interiors. Current trends indicate, however, that consumers and interior designers are looking for solutions with a more interesting effect, giving kitchens an unusual character. The answer to this search is kitchen furniture fronts using CNC technology.

The MELAFOL technology, developed by us and successfully used for years, eliminates all limitations related to the decoration of furniture boards. Thanks to it, we can apply both a subtle pattern and deep grooves on their surface. We are able to mill geometric shapes as well as unusual and irregular patterns according to the design or the customer’s intention.

All while ensuring high-quality workmanship and perfect finishing precision. For the production of cutters in the MELAFOL technology, we use single-sided laminated MDF boards with a thickness of 16 to 25 mm. We cover them with a polymer film in the process of vacuum pressing. During production, we use boards, adhesives and foils covered by the required approvals and certificates, recognized both in Poland and abroad. This means that MELAFOL products can also be distributed outside the country.

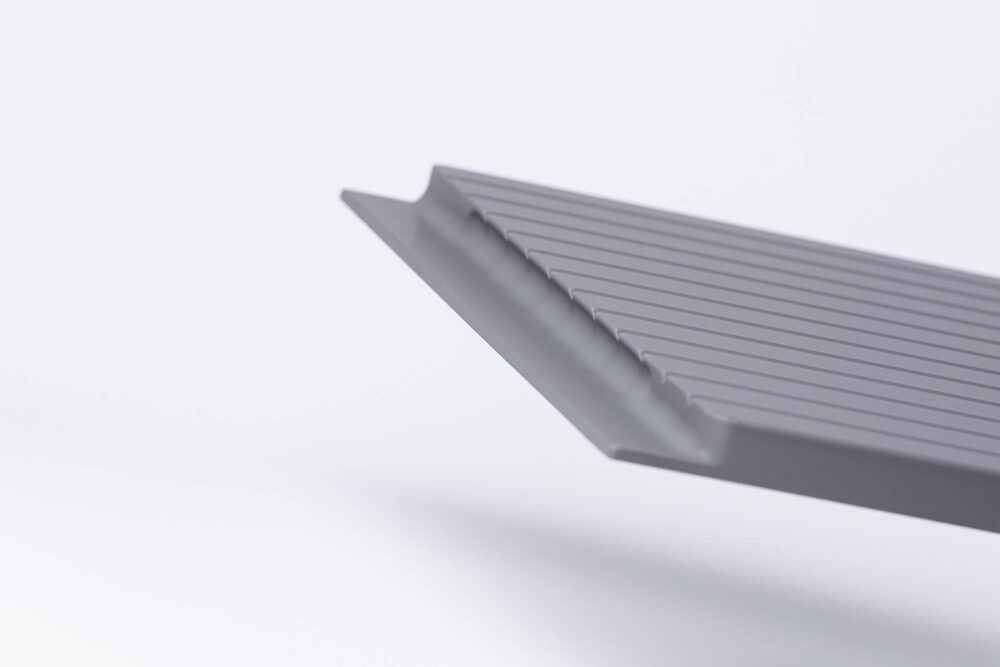

Our newest MELAFOL collection, which includes fronts with a fashionable slat wall structure, deserves special attention. Kitchen furniture fronts with such a finish offer an original look, combining aesthetics with durability that we provide to our products.

Get to know all the structures of our collection: The new MELAFOL collection: Furniture fronts with a slat wall structure

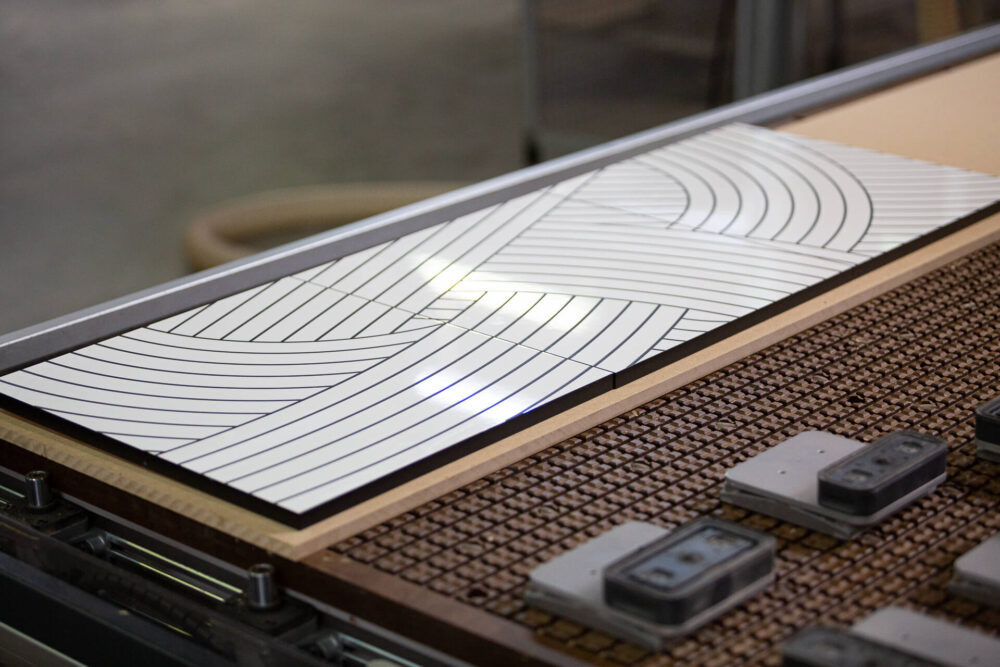

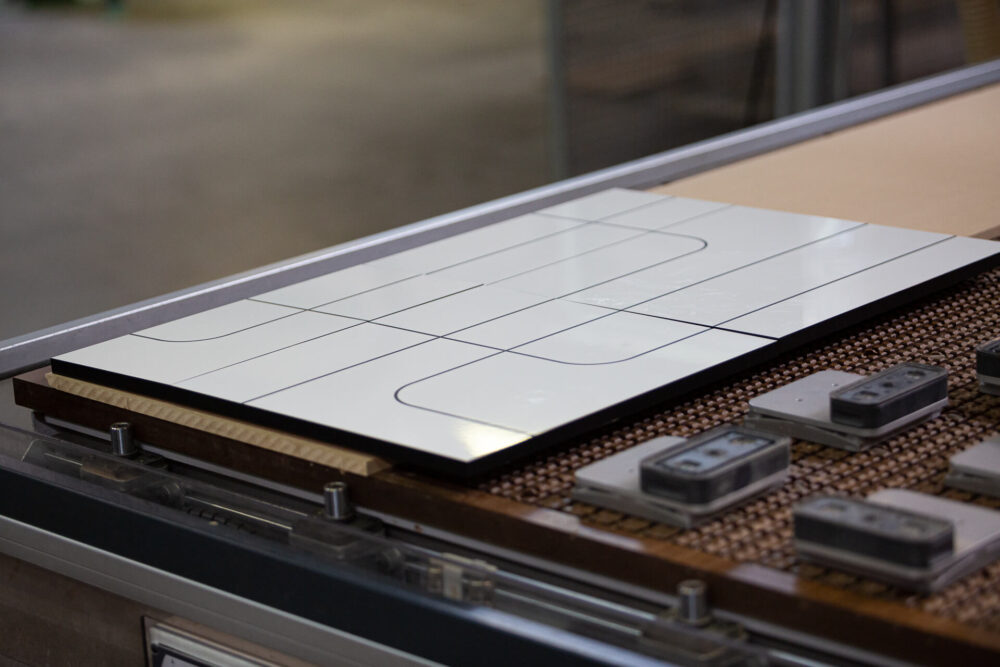

The strength of the MELAFOL line is the possibility of creating furniture fronts of any structure. Thanks to a modern CNC machine tool park, we are able to apply any project on the board and give it the desired finish – also with the use of two-colour foil. This effect is offered by our MICRO MILLING™ technology, in which we cover the front with foil in two colours, 200 μm to 300 μm thick. The outer layer is milled according to the design in the depth range of 50 μm-100 μm. For this purpose, we use specialized Alphacam software, which enables the import and processing into machine codes of very complex graphic designs made by our designers or received from the client. Specialized copying units with real-time electronic thickness measurement and diamond cutters are used for processing.

Contact

Do you have questions? Contact us.

We will be pleased to answer all questions about MELACO’s offer, terms of cooperation and orders. Write or call us.

Contact

Melaco sp. z o.o.

ul. Ciepielowska 9

67-100 Nowa Sól

Poland

SALES DEPARTMENT

Agata Sroczyńska

Sales Coordinator

SALES DEPARTMENT

Beata Prałat

Sales Specialist