Ecology is more than an obligation – it is an opportunity

Changes in European Union legislation aimed at promoting sustainable production and reducing CO2 emissions provide an important impetus for furniture companies to implement eco-friendly solutions. These activities not only contribute to environmental protection, but also open up new business opportunities, especially on European markets where ecological standards are becoming increasingly stringent.

However, caring for the environment is more than an obligation – it is also an opportunity for brands to build stronger trust and loyalty among consumers. Companies that actively engage in environmentally friendly activities are gaining in the eyes of customers, who are increasingly choosing socially and environmentally responsible brands.

However, despite growing environmental awareness, the furniture industry still faces a number of challenges in implementing sustainable practices. Education of both consumers and manufacturers is key in the transformation of the industry. Understanding the benefits of green solutions, both in terms of environmental protection and potential business benefits, is essential to accelerate this change.

At Melaco, we understand these challenges and opportunities. Our products and actions reflect a commitment to promoting sustainability in the furniture industry. We invite you to read on to learn more about our inspirations and solutions that meet the needs of a green future.

A sustainable future starts with sustainable production

At Melaco, we have understood the importance of operating in the spirit of sustainability and have taken concrete steps to make our production environmentally friendly. Our investments in green solutions and technologies are proof that environmental responsibility is an integral part of our business strategy. These include, among others:

1. The use of certified raw materials: We use environmentally certified materials, such as FSC®-certified wood, in our production. This ensures that our products are made from sustainably sourced raw materials. In addition, these raw materials have reduced formaldehyde emissions, which contributes to improved air quality and user health.

2. Reducing CO2 emissions: We have introduced a number of measures to reduce our carbon footprint, including investment in modern production technologies that minimise our carbon footprint.

3. Optimising production processes: As a result of an extended process audit, we have identified areas in the production process, identified and implemented measures that have already resulted in significant energy efficiency improvements. In addition, we are gradually replacing light sources with LEDs, which are modern, efficient and have a high energy yield.

4. Recycling and optimisation of production processes: We focus on recycling and the efficient use of raw materials, which allows us to reduce waste and increase the efficiency of our production processes. We are implementing polymer films that are produced from recycled pellets, the so-called R-PET.

5. Environmental education and awareness: we actively work to educate and raise environmental awareness among both our employees and business partners. We believe that together we can contribute to a better future for our planet.

Also read: European Green New Deal in Melaco – how we care for the environment →

Furniture in line with the ecological trend. Our inspiration

In addition to our drive to introduce sustainable production, we are constantly expanding our range of products to help our business partners implement their own green strategy. We offer a wide range of products and solutions that are designed to minimise environmental impact. From PER laminate to R-PET film to the innovative FLORA and FOREST fronts, our products combine an ecological approach with the highest quality and aesthetics. With MICRO MILLING™ technology and the Flick&Click™ system, we offer solutions that are not only environmentally friendly, but also efficient and practical for everyday use. Discover them all.

R-PET films – Comfort Oak finish

The innovative R-PET films are an example of the use of recycled raw materials. The Comfort Oak finish, with its natural oak texture and available in a wide range of colours, combines aesthetics with an ecological approach, offering a sustainable and aesthetically pleasing solution for a variety of furniture projects.

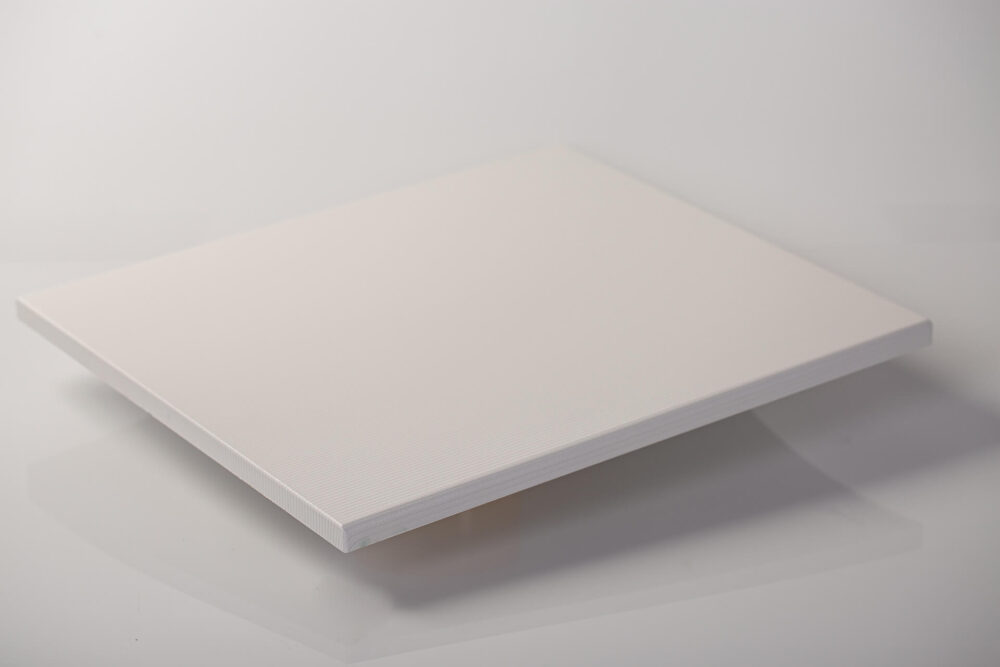

PET laminate – the ecological alternative to PVC

PET laminate is an eco-friendly alternative to traditional PVC. It is an environmentally friendly solution which, at the same time, does not compromise on quality and aesthetics, ensuring the durability and elegant appearance of furniture products.

FLORA fronts finished with a film made of natural ingredients

FLORA fronts are covered with a foil made from natural ingredients – salt and ethylene from raw pine oil. Available in two unique textures: Stripes and Pyramid, these innovative fronts offer a unique and ecological solution for modern interiors.

Also read: Ecology and design. Discover the innovative FLORA foil made of natural raw materials →

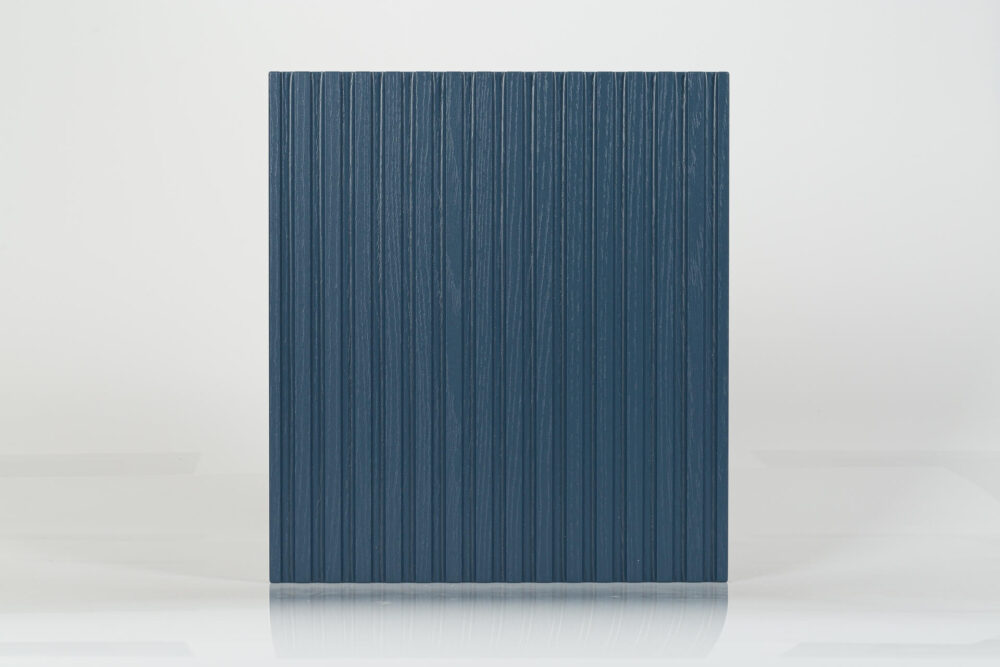

FOREST fronts – for interiors in the spirit of ecology

We should also bear in mind the trend of creating interiors with structures reminiscent of those found in nature. FOREST fronts with a natural wood motif are an example – an ideal solution for those who wish to create an ecological interior. The popular lamellar profiling adds to their unique character.

Marble, concrete and stone structures

In addition to natural wood textures, we also offer finishes reminiscent of real stone. Among these, concrete and marble structures are still the most popular, giving a more refined character to the interiors and, thanks to the use of certified wood-based materials, their price is more attractive to the final consumer.

Lamella structure – a modern alternative to a slat-wall

The lamella structure is the answer to the growing popularity of traditional lamellas. They bring a natural wood effect to interiors with a modern touch. This unique structure is used in both fronts and furniture boards, created within the MELAFOL production line and thanks to the advanced MICRO MILLING™ technology.

Also read: Our realization: Profiled furniture fronts →

Flick&Click™ tool-free fitting system

The Flick&Click™ system is based on the patented Threespine® tool-free assembly technology. It is a solution that saves on transport and reduces the size of the shipment. Thus, the system contributes to reducing CO2 emissions while offering convenience and efficiency in furniture assembly. In addition, it reduces the amount of steel and plastic fittings, which reduces the carbon footprint at the manufacturing stage, but also makes the process of recycling used furniture more efficient in the future by eliminating the need to separate wood components from steel and plastic.

Also read: Tool-free Flick&Click™ furniture assembly: CORNER90 vs. M45 →

System and modular furniture

System and modular furniture gives end consumers the opportunity to decide on the number and type of furniture pieces they need. In this way, they can be tailored to their own space and needs, reducing overproduction and environmental impact. The use of Threespine® tool-free assembly technology makes it easier for consumers to create their own furniture, while reducing the need for bulky shipping of finished carcasses.

Melaco: Your partner in the pursuit of ecological solutions

In the face of increasing environmental awareness and changing market expectations, taking action to reduce the environmental impact of operations is becoming not only an obligation but, above all, the responsibility of every furniture manufacturer. At Melaco, we believe that every step towards sustainability is a step towards a better future for all of us.

Don’t wait, join the ranks of conscious manufacturers who are already shaping the future of the furniture industry in harmony with nature. Contact us to learn more about our eco-friendly solutions and start creating the furniture of the future with us.

Agata Sroczyńska

sales coordinator

Contact

Do you have questions? Contact us.

We will be pleased to answer all questions about MELACO’s offer, terms of cooperation and orders. Write or call us.

Contact

Melaco sp. z o.o.

ul. Ciepielowska 9

67-100 Nowa Sól

Poland

SALES DEPARTMENT

Agata Sroczyńska

Sales Coordinator

SALES DEPARTMENT

Beata Prałat

Sales Specialist