This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Why is ecology in furniture manufacturing so important?

Ecology has been leading the way in the furniture industry for many years. Of particular importance is the use of renewable raw materials – from certified timber to innovative materials such as coconut fibres or rush fillings. This is not only due to various EU directives; companies introducing green solutions reduce their carbon footprint and build a competitive advantage by responding to the needs of environmentally conscious customers. Implementing closed-loop economy principles and using biodegradable materials is becoming an industry standard that determines the future of furniture. Manufacturers who want to remain competitive must implement sustainable solutions now, from natural resin-based materials to recycled furniture films.

Fronts made in MicroMilling™ technology

The latest environmental trends in the furniture industry

The furniture industry is increasingly using environmentally friendly materials such as wood from FSC® certified sources, bamboo and biodegradable plastics. Recycled materials, including wood fibres and R-PET plastics, are also popular. Furthermore, manufacturers are implementing modern technologies to minimise their environmental impact. This includes the automation of production processes, the use of renewable energy sources and the optimisation of resource consumption. Certificates confirming the ecological origin of materials and the safety of products for users are becoming increasingly important. The avoidance of toxic substances in the production process is also a particularly important trend. This is why Melaco uses wood-based boards that meet the most stringent formaldehyde emission requirements.

Fronts and worktop made of R-PET foil

Melaco’s eco-friendly solutions

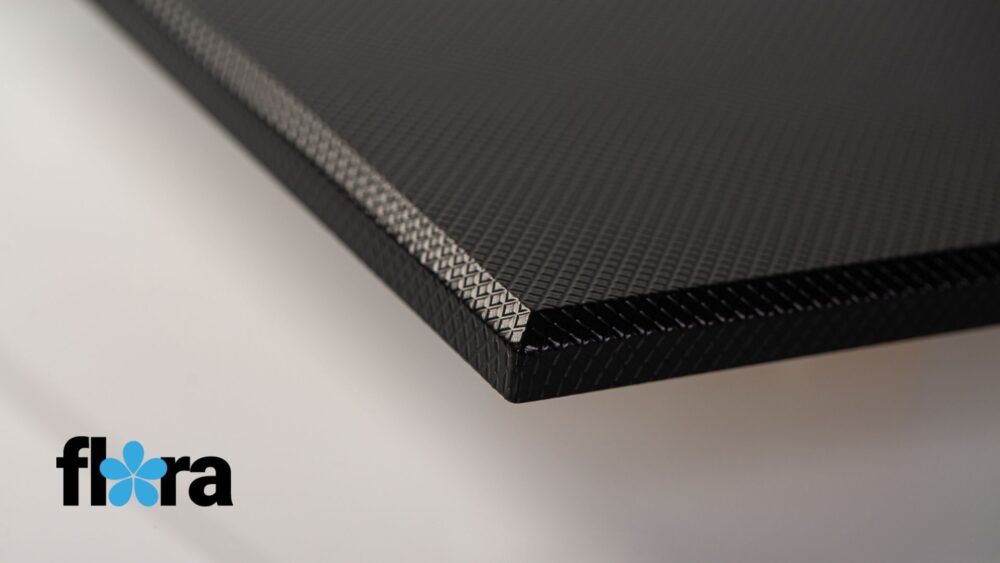

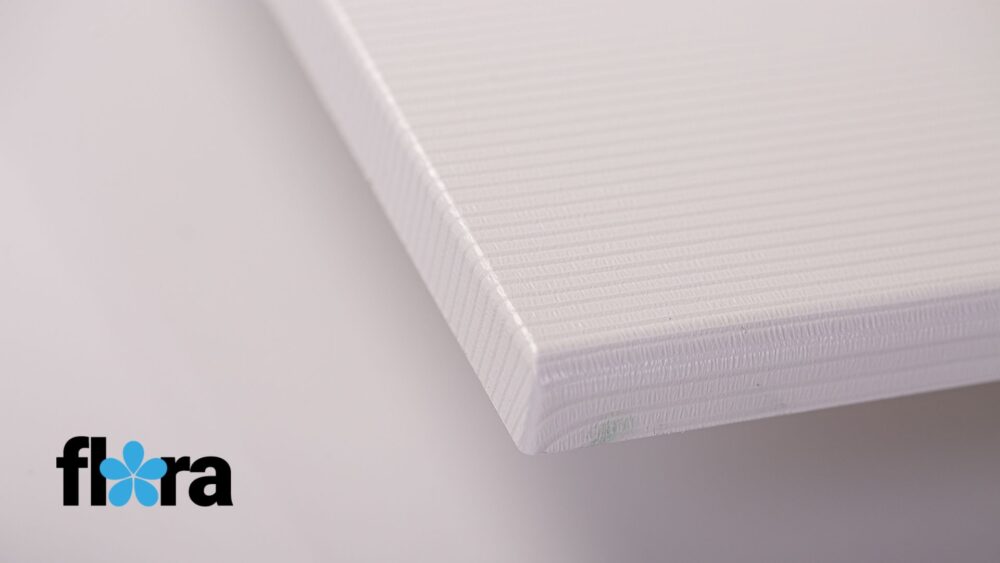

Fronts covered with FLORA foil

FLORA is an innovative biobased PVC film that combines ecological solutions with high functionality. It consists of 57% salt and 43% ethylene derived from crude pine oil from certified second-generation biomass. The use of biobased PVC reduces CO2 emissions by up to 90% compared to conventional solutions. FLORA film offers a wide range of finishing options, from supersaturated to high-gloss surfaces, as well as a variety of printed and embossed designs. The material works well in 1D, 2D and 3D applications, while remaining fully compliant with recycling requirements. The production of FLORA film takes place in the European Union, which guarantees compliance with strict environmental and quality standards.

MELAFOL fronts | 1. PYRAMIDS structure in black | 2. STRIPES structure in white | FLORA foil

Comfort Oak in colors: 1. Snow White PREMIER MATT | 2. Dark Cream PREMIER MATT | 3. Sage Green PREMIER MATT | 4. Dusk Blue PREMIER MATT | 5. Navy Blue PREMIER MATT | 6. Dark Charcoal PREMIER MATT | 7. Black PREMIER MATT

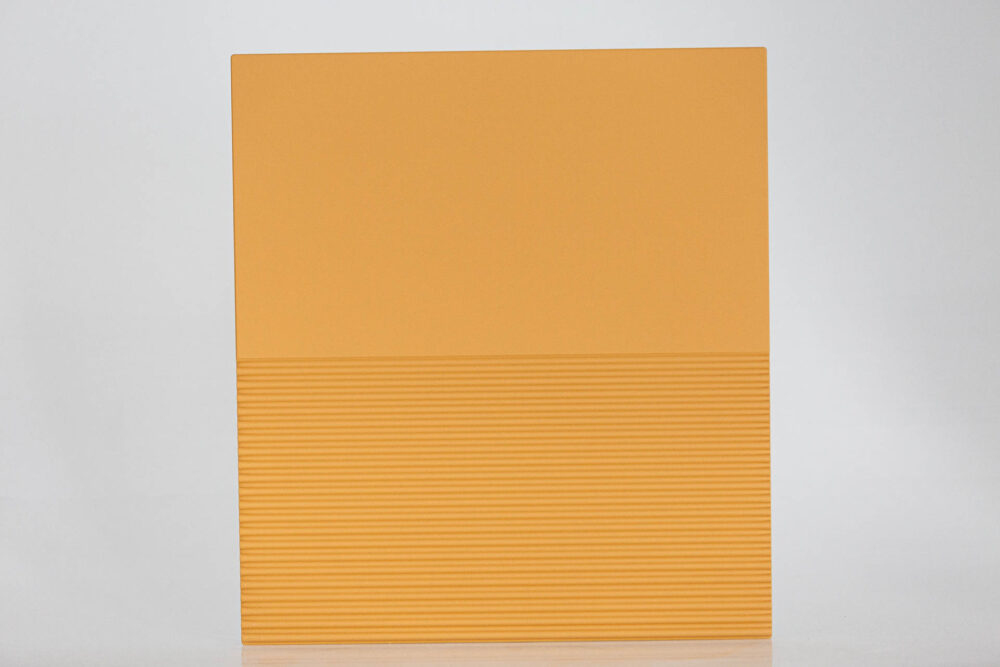

PET laminate

The PET laminate used by Melaco to manufacture COMPLETE SKIN furniture boards is an environmentally friendly alternative to traditional PVC materials, which fits in with the growing trend of sustainability in the furniture industry. The use of PET laminate makes it possible to significantly reduce the negative impact on the environment, while maintaining the aesthetics of the products. The material is characterised by exceptional durability, making it an ideal choice for furniture manufacturers who want to meet the expectations of environmentally conscious consumers. Through the use of PET laminate in its components, Melaco supports its business partners in their environmental strategies by offering solutions that combine innovation with environmental responsibility.

Complete Skin furniture boards | matt finish with fine Stardust particles

MELAFOL fronts with FSC® certification and reduced formaldehyde emission

The MELAFOL fronts offered by Melaco exemplify the company’s commitment to sustainability. The components are distinguished by their FSC® certification, which confirms that the raw materials used in production come from responsibly managed forest sources. In addition, the MELAFOL range is characterised by reduced formaldehyde emissions, making the products safer for the health of users and environmentally friendly. Thanks to the use of one-sided laminated MDF boards from 16 to 25 mm thick, and polymer film in the vacuum pressing process, these fronts are characterised by high quality workmanship and durability. Melaco, through its products, enables furniture manufacturers to offer products that meet the highest ecological and aesthetic standards, thus responding to the needs of conscious consumers looking for sustainable and responsible solutions.

MELAFOL fronts | 1. Wave + Płasko, Ceramic Red | 2. Wave ½, Toffie

Sustainable production

Melaco implements sustainable manufacturing through a number of initiatives that minimise environmental impact. The company focuses on optimising energy and resource consumption, which includes investment in modern production technologies and efficient waste management. Melaco uses responsibly sourced raw materials, as evidenced by certifications such as the aforementioned FSC® certification – which the company has already boasted since 2014. In addition, the company places great emphasis on reducing emissions of harmful substances, including formaldehyde, which is in line with European environmental standards. Thanks to such measures, Melaco not only meets the legal requirements, but also responds to the growing expectations of its customers for environmentally friendly products.

Read more about the European Green New Deal in Melaco here.

Are you looking for a business partner who is not careless about ecology? Contact us and find out more about Melaco’s production capabilities.

Contact

Do you have questions? Contact us.

We will be pleased to answer all questions about MELACO’s offer, terms of cooperation and orders. Write or call us.

Contact

Melaco sp. z o.o.

ul. Ciepielowska 9

67-100 Nowa Sól

Poland

SALES DEPARTMENT

Agata Sroczyńska

Sales Coordinator

SALES DEPARTMENT

Beata Prałat

Sales Specialist