This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Modern lines, geometric designs, minimalistic forms

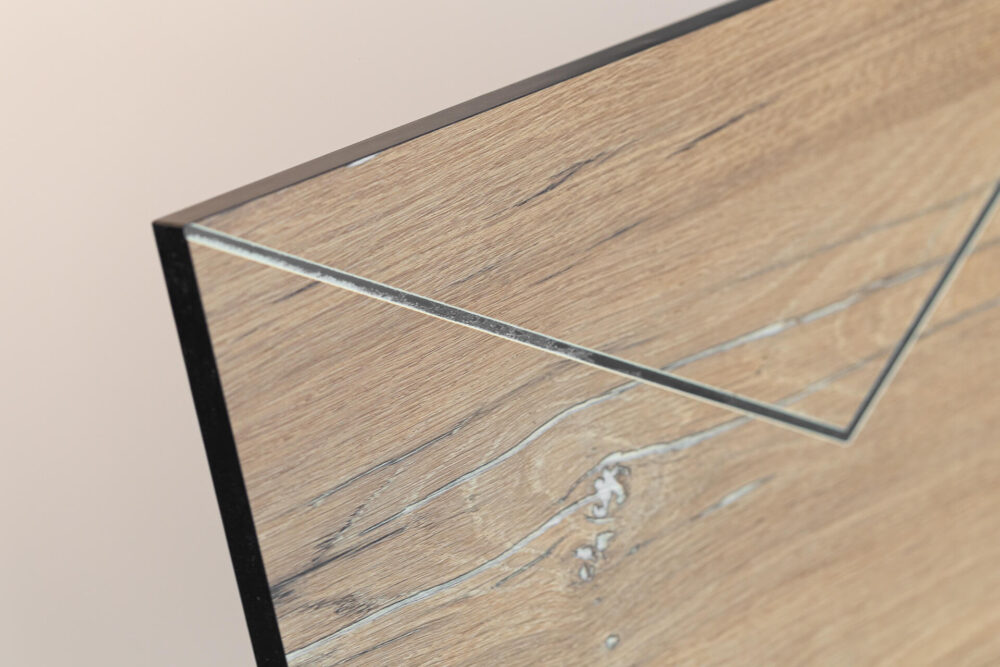

The MICRO MILLING™ technology is the key to creating furniture and furnishings that are responses to the latest trends. This offer is intended for those who are looking for more than just practicality from their furniture. Based on the specialist Alphacam software, it combines precision, technology and creativity, enabling the most complex graphic designs to be converted into machine codes. This means that by using the MICRO MILLING™ technology, we are able to give any of our projects real shape.

Also read: MICRO MILLING™ technology – new inspirations for unusual furniture fronts

Besides the creative possibilities, MICRO MILLING™ also guarantees durability. Our laminating process, that uses a high-quality, polymer-based foil acquired from renowned suppliers, additionally makes the surface more water-resistant. In addition, the use of the reactive PUR adhesive renders the MICRO MILLING™ decorated fronts resistant not only to moisture but also to higher temperatures. The surfaces are also easy to keep clean, which is bound to be appreciated by end consumers.

How does the MICRO MILLING™ surface decoration process work?

The technology focuses on the precise processing of a COMPLETE SKIN or MELAFOL board, and the process itself requires a specialised approach – we cover the front of the board with a film or veneer between 200 μm and 300 μm thick. Next, the outer layer is milled according to the design, using specialised copying units with real-time electronic thickness measurement and diamond cutters.

Universal use

The high durability parameters and unlimited possibilities in terms of the milled designs allow the MICRO MILLING™ technology to be used in many kinds of produce, such as:

- Furniture fronts

- Decorative panels

- Sliding wardrobe doors

- Other elements of furniture

Also read: MICRO MILLING™ lamellar fronts vs. solid-coloured MDF-based fronts

The limitations do not also apply to interior styles. Unique details or additional textures will give your furniture collections exactly the character you want. Simple, geometric designs, few details but with a high degree of precision – these features are the perfect backdrop for a minimalistic design. With this technology, you can create subtle lines and patterns that add elegance without overloading the space. Geometric shapes and clean lines are also used by enthusiasts of modern interiors and raw, industrial rooms. In combination with concrete or wood, the effect of subtle striations will be even more interesting.

The extraordinary designs will also enhance the Boho style furniture, which loves different textures and the not-so-obvious breakage of colours and the geometry of a room. They also fit perfectly into the Art Deco style collections, where the rich patterns underline the luxury of the entire room. Plant motifs and ornaments will be appreciated by both rustic and organic style connoisseurs.

MICRO MILLING™ technology – inspirations from MELACO

Now that you know the possibilities of our innovative MICRO MILLING™ technology, we invite you to stop by our inspiration gallery. Here, you will find a few examples of how this incredible process can revitalise a variety of interior styles. Allow yourself to be inspired and see how our solutions may affect your furniture range. Want to know more? Get in touch with us! We will gladly answer all of your questions and will help in the realisation of your vision. Together, we will create something truly special.

Contact

Do you have questions? Contact us.

We will be pleased to answer all questions about MELACO’s offer, terms of cooperation and orders. Write or call us.

Contact

Melaco sp. z o.o.

ul. Ciepielowska 9

67-100 Nowa Sól

Poland

SALES DEPARTMENT

Agata Sroczyńska

Sales Coordinator

SALES DEPARTMENT

Beata Prałat

Sales Specialist