This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

It provides high resistance to moisture and high temperature, and also – makes the finished product uniform thanks to the use of identical foil on the board and edges. What does the COMPLETE SKIN DOOR production process look like in Melaco and what solutions do we use at its various stages? Take a look at our machine park.

COMPLETE SKIN DOOR – technologies and solutions

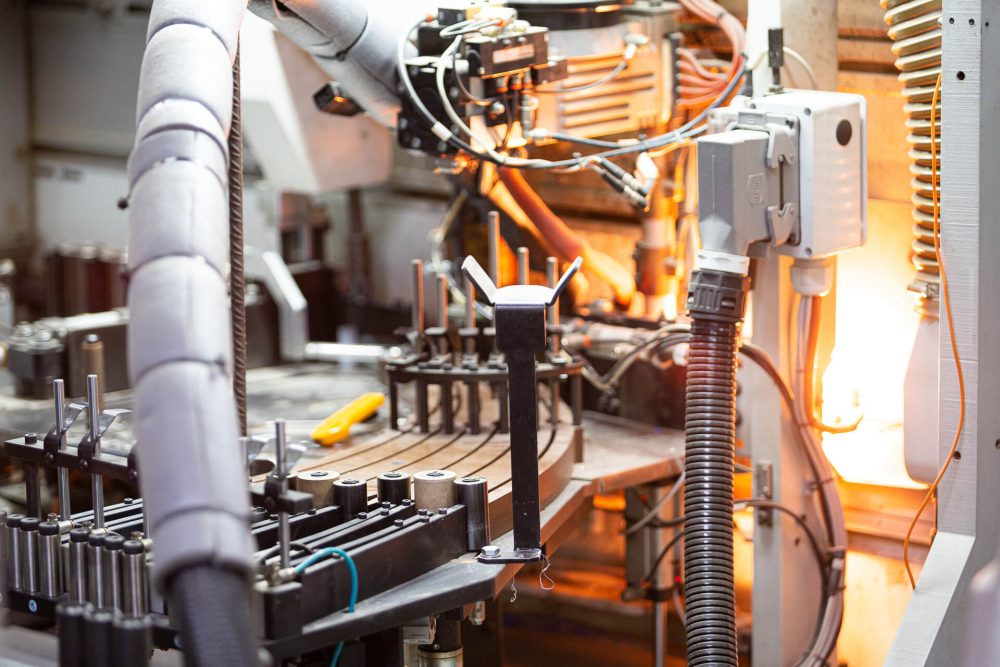

When creating our product, we use several devices and technologies that provide it with excellent strength parameters, precise dimensions and a perfect finish. These include: the SELCO panel cutting center and the BIESSE STREAM automatic line for formatting and wrapping narrow planes.

See what machines and devices we work on every day: Machinery park in Melaco

The use of the same type of foil with dimensions from 0.3 to 0.6 mm on the plane of COMPLETE SKIN boards and on the edges allows us to obtain the 3D effect, i.e. a monolithic body. It is also possible to apply different colors of the foil on the board and its edges – depending on the effect that the client wants to achieve. We use polyurethane glue to apply the foil to the boards, ensuring maximum resistance to moisture and high temperatures. In this way, we create a product that works great in all types of furniture, in particular kitchen and bathroom furniture.

How does the creation process of COMPLETE SKIN DOOR go step by step?

Board preparation and cutting

The first step is to prepare the board for processing. According to the customer’s order, we select MDF or chipboard suitable for thickness and finish. The board is cut at the SELCO cutting center. It can be a double-sided laminated board or a more valuable board finished in a high gloss or COMPLETE SKIN supermat. It is cut into forms in gross dimensions.

Prepared forms are put on a pallet with an accompanying label so that machine operators know what they are collecting and how the further steps should proceed. Labels with information about production processes accompany the product at every stage – thanks to this, the staff knows exactly how to prepare it for further operations, which processing programs to use, and what color and type of foil to choose. We also record all production stages in our internal ERP system.

Wrap narrow planes

The BIESSE STREAM EDGE – MDS line is used for wrapping narrow planes and formatting to a linear dimension with an accuracy of 0.2 mm and an angle with an accuracy of 0.5 °. The whole process is automatic and initiated by reading the barcode from the label, where such data as: net size, color and thickness of the edge, plate type, number of pieces in the customer’s order are collected.

How does it look like in stages?

- On cutters, excess material is collected on the part.

- Glue and edging are applied.

- Capers cut off the excess edge.

- Profile cutters pick up excess material on the top and bottom of the plate.

- The veneer at the corners is profiled with a set of finishing cutters, which also machine a profiled postforming edge with a radius of 2 to 65 mm.

- Profile scrapers clean the element of excess glue.

- The cleaning brushes remove excess adhesive and machined debris.

- At the end of the line, special heaters were installed, which by blowing air at a temperature of about 200 ° C-250 ° C cause the rim surface to vitrify, giving it a smooth and uniform texture.

All steps are performed on the line automatically with a feed speed of 20 m / min. The operator supervises the process and verifies the machining parameters. If there are further processing steps, for example drilling holes, the products are transferred to the next station: CNC machining center or CNC drilling center.

Quality control

Verification of the compliance of our products with the order takes place at every stage of production. Employees responsible for individual stages make sure that the product they produce complies with the guidelines before it goes to the next employee.

The final control stage follows the entire edge banding process on the STREAM EDGE line. Then the final product inspection takes place. Only after this stage is the product ready to be sent to the customer.

Contact

Do you have questions? Contact us.

We will be pleased to answer all questions about MELACO’s offer, terms of cooperation and orders. Write or call us.

Contact

Melaco sp. z o.o.

ul. Ciepielowska 9

67-100 Nowa Sól

Poland

SALES DEPARTMENT

Agata Sroczyńska

Sales Coordinator

SALES DEPARTMENT

Beata Prałat

Sales Specialist