This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Product parameters and base material

Bathroom furniture modules have the dimensions of a cube. Their dimensions are 250 mm x 250 mm x 250 mm. For the production of the cabinets, we chose high-quality, low-emission FSC®-certified boards that meet the requirements of DIN EN 16516 with the following parameters:

- Body: waterproof laminated chipboard P3, thickness: 16 mm, covered with a polymer film in the HOT MELT LAMINATION – COMPLETE SKIN technology.

- Rear wall: varnished HDF board, thickness: 3 mm.

- Front: laminated MDF board, 3 mm thick, covered with a polymer film in the 3D membrane-vacuum technology – MELAFOL.

Applied technologies

In addition to high-quality materials, we also use our innovative technologies, thus ensuring the required quality of finished products. To make the body, we used the proven HOT MELT LAMINATION technology, which offers very even application of a controlled minimum basis weight of PUR reactive glue, on which a polymer film is immediately applied. Such a finish, combined with an excellent quality adhesive system, is characterized by perfect smoothness and exceptional quality, as well as resistance to moisture and elevated temperature.

You can read more about it here: HOT MELT LAMINATION technology – durable and durable furniture

Sticking the elements in the membrane-vacuum technology, which we used during the production of cabinet fronts, allows for a perfect application of a polymer film on any surface, also the milled one. In the case of bathroom furniture modules, this technology allowed us to provide the elements with a perfect finish in three planes – on the surface and edges of the forms.

Find out more: MELAFOL furniture fronts

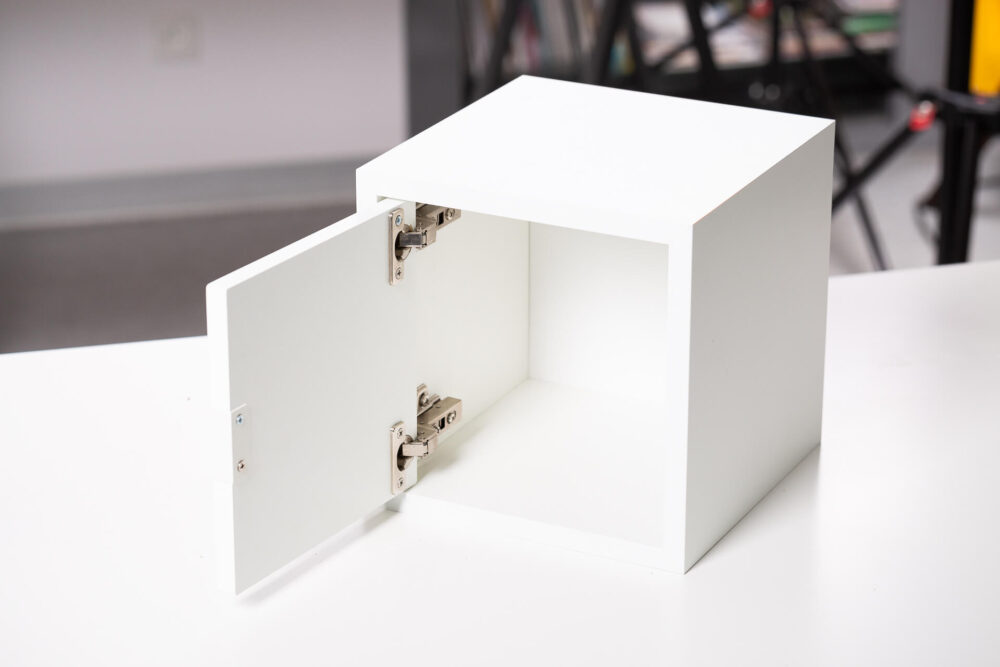

Flick&Click™ furniture system based on Threespine® toolless assembly technology

The Flick&Click™ system is also an innovative solution. We reached for the tool-free Threespine® assembly technology. In the construction of the body, we used folding profiling in three corners and the “MITER JOINT 45⁰” profile in the fourth corner.

In the solution used, assembly glue is applied in three corners, and the whole thing is closed in the fourth corner thanks to the mechanical locking function:

The advantages of the product

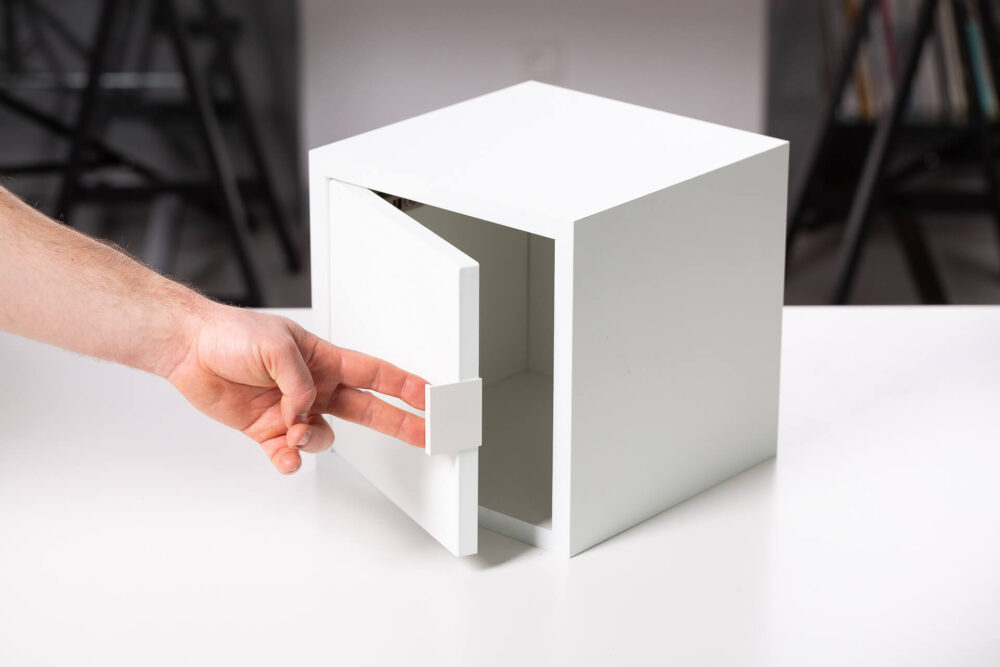

Modules for the bathroom are characterized by high aesthetics and quality of surface finish. Thanks to the 45⁰ corner finish, no connections are visible, and the products gain an elegant and very modern design.

However, these are not all their advantages. The recessed front completes the minimalist character of this product, and the SUPERMATT surface finish adds to its aesthetic value.

TheFlick&Click™ system – use

Due to the different types of connections, the Flick&Click™ system can be used in virtually any type of product and according to the manufacturer’s needs. It works great with shelves and bookcases, coffee tables and desks, bedside and bathroom cabinets, as well as in modular furniture and furniture for mansard rooms .

As our last project shows, this system works great also in the production of dedicated products, such as the aforementioned furniture modules for the bathroom.

Its unique advantage is the ease of assembly, which will be appreciated by end consumers, but also the related limitation of the product dimensions during shipment.

Do you want to check if the Flick&Click™ system is also suitable for your products? Contact us – we will be happy to answer any questions and prepare a prototype:

Contact

Do you have questions? Contact us.

We will be pleased to answer all questions about MELACO’s offer, terms of cooperation and orders. Write or call us.

Contact

Melaco sp. z o.o.

ul. Ciepielowska 9

67-100 Nowa Sól

Poland

SALES DEPARTMENT

Agata Sroczyńska

Sales Coordinator

SALES DEPARTMENT

Beata Prałat

Sales Specialist