This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

What distinguishes COMPLETE SKIN furniture boards and panels?

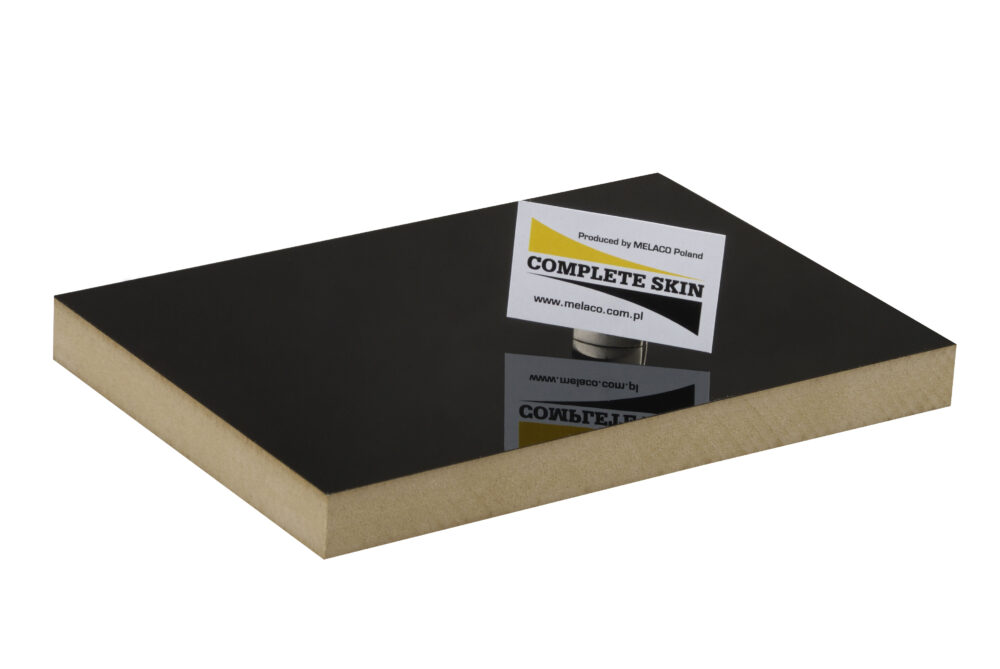

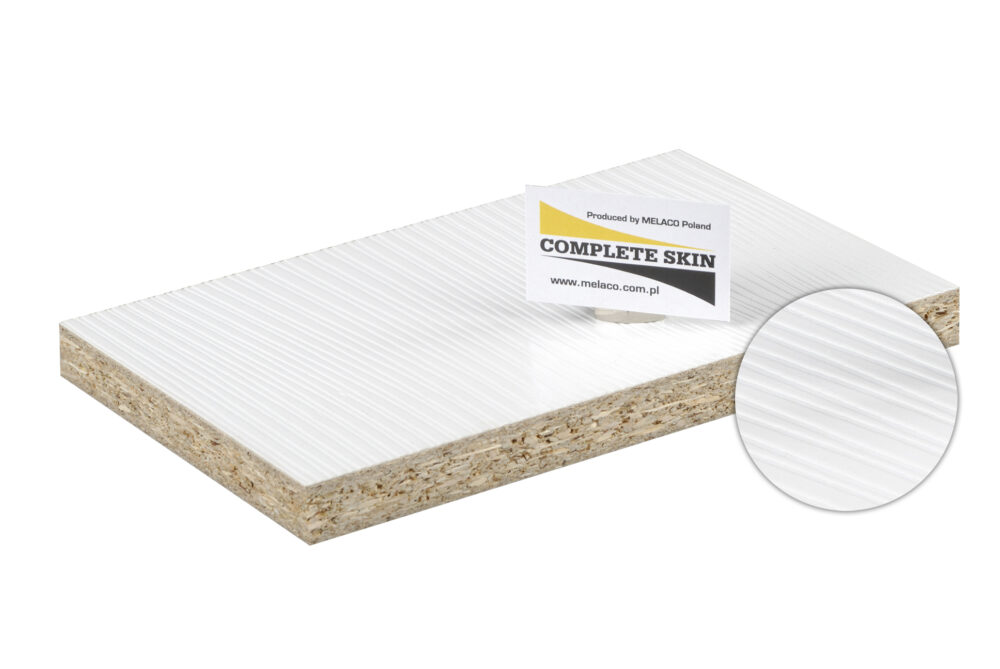

COMPLETE SKIN furniture boards and panels are characterized by extraordinary durability and versatility. At Melaco, we use the highest quality MDF, particleboard, and polymer films from reputable manufacturers. Our furniture components are manufactured using advanced HOT MELT LAMINATION wrapping technology, with innovative PUR adhesives.

In this modern technology, PUR reactive adhesive is evenly applied to the particleboard or MDF, and then covered with a polymer film (PVC, PP, PET, or FINISH). Such a bonding process makes it possible to achieve not only a perfectly finished surface of furniture components but also a durable joint, which is characterized by resistance to moisture and high temperatures. All this makes COMPLETE SKIN furniture components that can also be used for the production of furniture for such demanding rooms as kitchens and bathrooms.

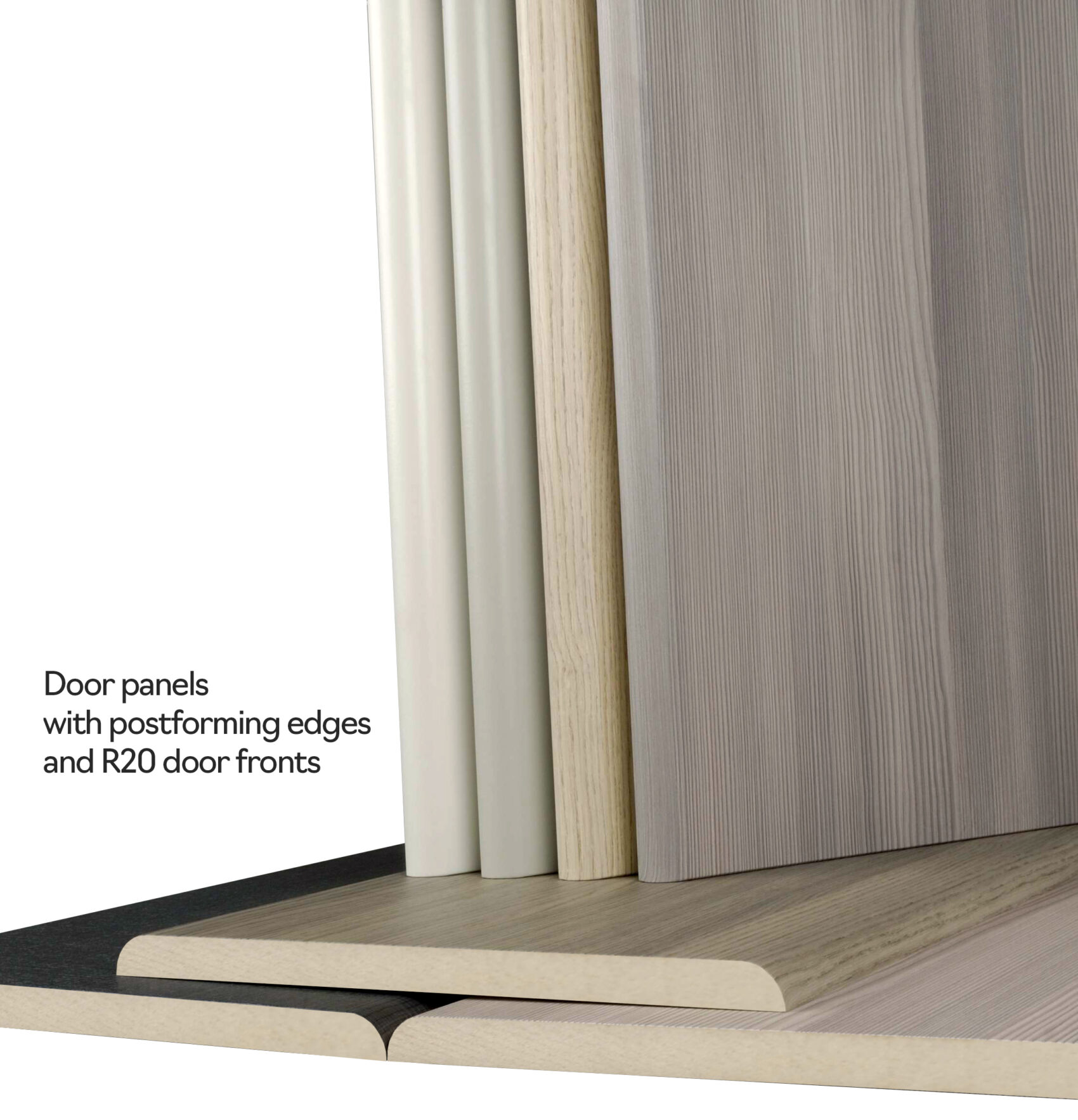

The technologies available in our machine park also allow us to finish the edges of the components on one or both sides using POSTFORMING technology, giving the edges of the board an elegant finish without a visible joint. What sets us apart from the competition is that our advanced technology allows us to finish narrow, elongated edges at the same time. This solution makes it possible to achieve an elegant finish on the board without a visible joint. In addition, we also offer many available types of edge profiling.

How does the HOT MELT LAMINATION process work? Read in our post: HOT MELT LAMINATION technology – durable and long-lasting furniture →

When looking for the ideal materials for furniture production, it is worth paying attention to the features that distinguish our furniture webs and boards. Here is a brief overview of their unique properties and technological innovations.

Versatility of COMPLETE SKIN furniture boards

What attracts the attention of many furniture manufacturers is the versatility of our COMPLETE SKIN product line. The panels and furniture boards in this collection are produced in dimensions dedicated to the customer. Whether we supply boards to furniture manufacturers for the kitchen, living room, bedroom, children’s room, or bathroom, we can tailor our products accordingly to meet the requirements in terms of thickness, color, texture, and dimension. As a substrate, we can use both particleboard and MDF — depending on the customer’s specifications, we take into account hygiene class, FSC® certification, or moisture resistance and ignitability class. We can easily adapt to specific project requirements.

Examples of the implementation of COMPLETE SKIN furniture boards and panels:

-

kitchen furniture,

-

room furniture,

-

bathroom furniture,

-

children’s furniture,

-

bedroom furniture,

-

closet front and side panels,

-

panels for interior and exterior doors,

-

large-scale components used in the furnishing of stores, exhibition facilities and other public buildings.

We supply manufacturers with ready-made formats

What’s more, we also supply COMPLETE SKIN board formats — these elements are cut to gross dimensions that can go directly to the production line for wrapping narrow planes. This is a great solution for companies that care about streamlining production. The advantages of using properly cut COMPLETE SKIN formats also include a significant acceleration of production time.

This streamlining allows customers to increase financial benefits, as they will be able to produce more furniture in much less time. Formats going directly to the production line will also make it possible to reduce waste from cutting and formatting boards, while also helping to minimize inventory to meet the needs of specific projects. This includes savings on the storage of production materials. Simply put, we will provide ready-made formats whose dimensions will be tailored exactly to each customer’s production plans.

Durable finish

COMPLETE SKIN furniture boards are characterized by exceptional durability, which makes them resistant to elevated temperatures and moisture. As a result, they can be safely installed even near ovens and stoves. Their high resistance to moisture, as well as scratches and scrapes, makes them an excellent choice for a variety of furniture components, from drawer fronts to cabinet doors.

Excellent surface quality

COMPLETE SKIN furniture boards are a synonym for the highest quality. Made with precision and attention to detail, they provide durability at the highest level. What’s more, at Melaco we make sure that the high quality of our products always goes hand in hand with aesthetics and design. Thanks to the use of the latest technologies and the best materials, our furniture boards guarantee not only a perfect finish, but also durability for many years to come. Regardless of the chosen structure or color of the finishing film – COMPLETE SKIN board surfaces are resistant to sunlight, elevated temperatures or moisture.

Ease of installation and processing

Thanks to such parameters as high surface hardness, very good adhesive bonding properties, and protection of glossy and matte board surfaces with a protective film, COMPLETE SKIN very well meets the requirements of technological processes in any modern furniture factory. This makes them an ideal choice for manufacturers looking for efficient production solutions. An investment in proven furniture boards from Melaco will therefore be conducive to achieving highly efficient production processes in any company.

We care about ecology when producing components

We are aware of the significance of corporate responsibility towards the environment, which is why our COMPLETE SKIN furniture boards are manufactured to the highest environmental standards. We make sure that our production processes are as environmentally friendly as possible, minimizing the negative impact on our planet. We properly segregate and recycle the waste left over from production. What’s more, we produce our components using film created on a recycled basis.

Possible finishing of COMPLETE SKIN furniture elements

Our assortment not only provides outstanding durability but also offers many finishing options to suit the diverse needs of our customers. With availability in various appearances, COMPLETE SKIN furniture boards allow you to create unique furnishings for any interior. We offer manufacturers a variety of surface finish options, including:

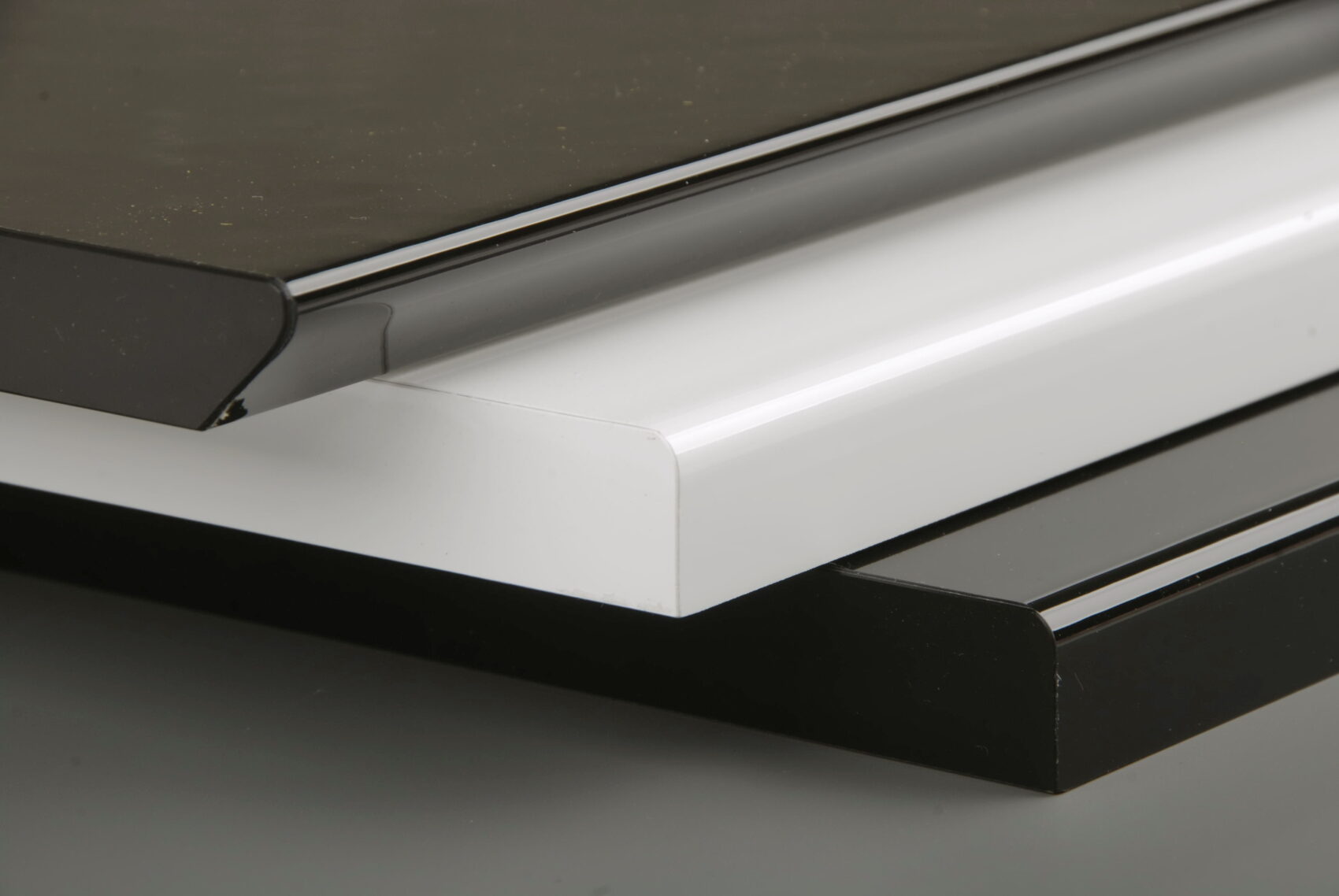

◾ High Gloss – a high-gloss finish that gives the furniture an extremely stylish look. This allows furniture manufacturers to meet the expectations of customers looking for unique and striking solutions. In addition, the surface of the board is coated with UV varnish, which makes components with this finish resistant to scratching and staining. As a result, they retain their attractive appearance for many years. What’s more, for protection in the process of transport and production, we use a transparent protective film.

◾ Premier Matt – an extraordinary finish that brings new quality and aesthetics to the world of furniture. Thanks to innovative PST (Physical Surface Treatment) technology, furniture boards in this finish surpass the standards of traditional surfaces. Boards in Premier Matt finish not only offer very low reflectivity, providing a truly deep matte effect but also make daily maintenance easier. Their extreme smoothness makes them easy to clean. Components of this type are resistant to scratches and abrasion. In turn, thanks to the anti-fingerprint function, the furniture always maintains its flawless appearance, as it is resistant to fingerprints.

◾ Metallic boards – a new dimension in elegance and durability, that brings freshness to the furniture industry. The metallic shades of hammered copper and brushed gold, add sparkle to any design. What’s more, metallic boards guarantee exceptional durability for furniture, making them an excellent choice for discerning customers. Their surface is resistant to scratches and damage.

◾ Star Dust (with glitter flecks) – the use of an innovative PET laminate with glitter flecks makes it possible to create extraordinary premium furniture collections. Combined with deep matte, it provides the elegance and durability characteristic of our popular Premier Matt finish. It comes in a variety of color options, including Shell White, Pearl Gold, Space Black, Sky Blue, Night Blue, and Pearl Bronze. This allows each manufacturer to find the perfect color combination to fit their projects.

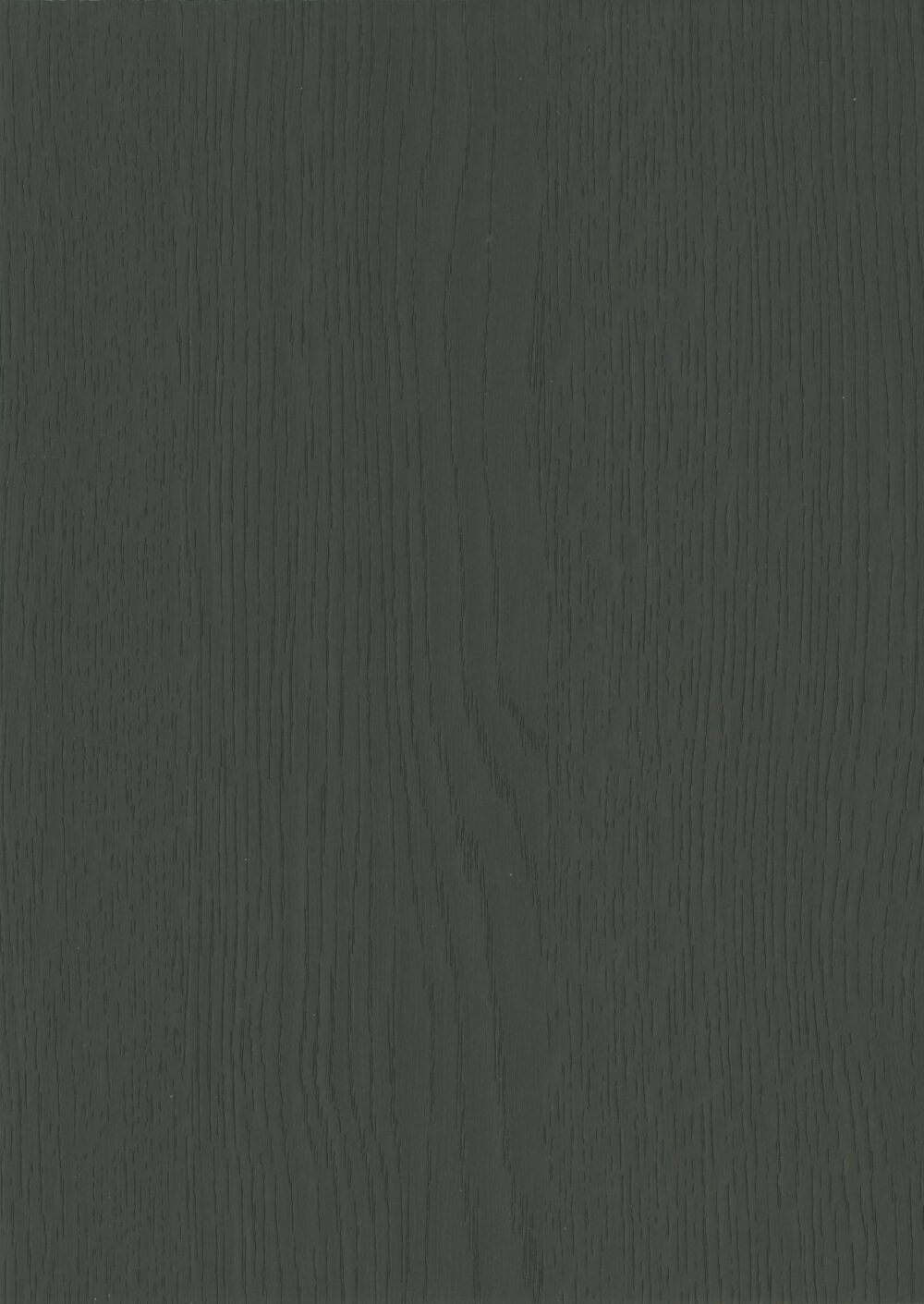

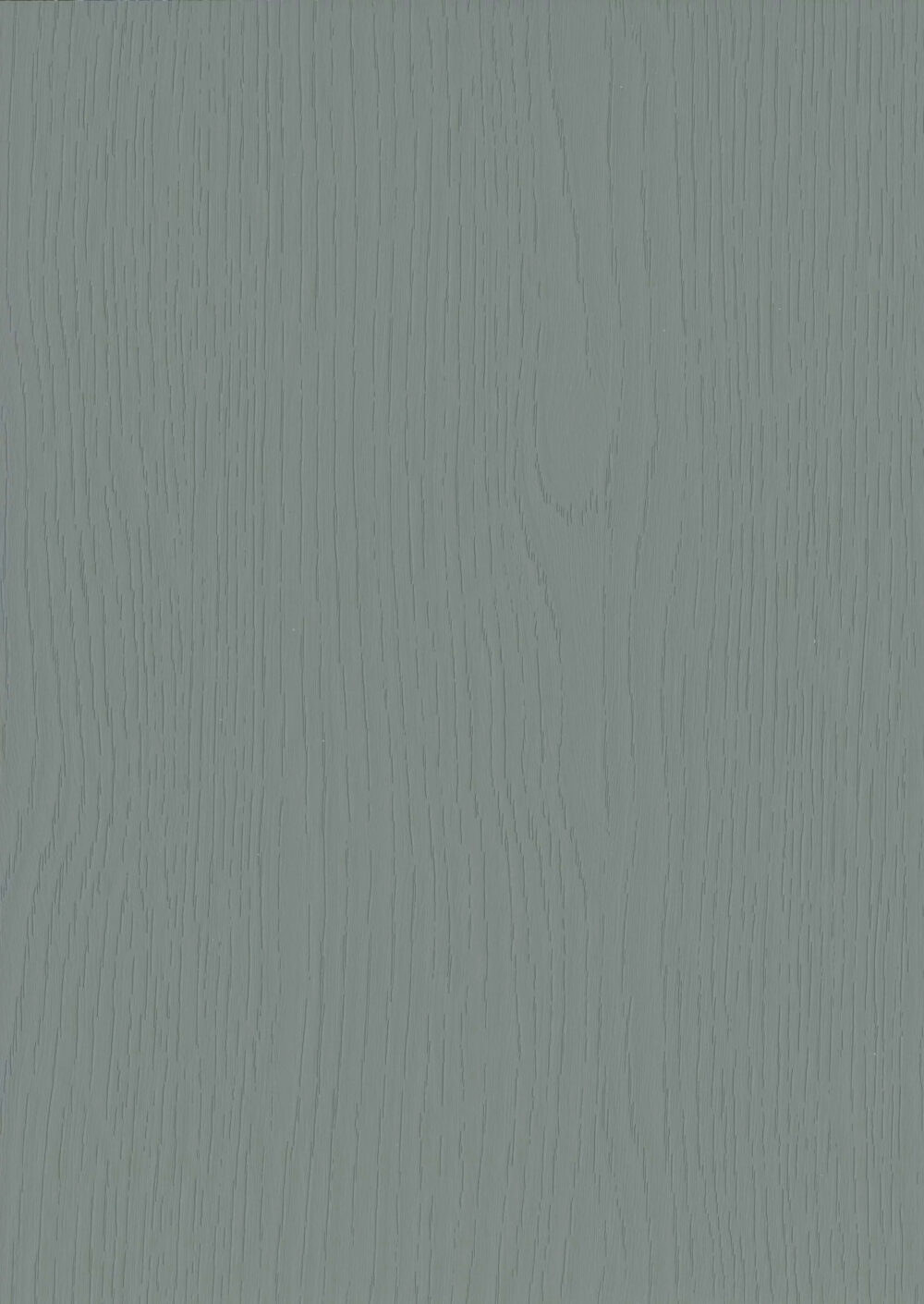

◾ Comfort Oak – a unique finish with a satin surface and oak texture, perfectly in line with the trend of creating interiors inspired by natural wood grains. The Comfort Oak finish is made of R-PET material, which means that recycled raw material was used in the production. This variant is available in a wide range of versatile colors, from white to gray to light or dark wood.

Learn more about our new products. View our product catalog →

Create durable and beautiful furniture collections with COMPLETE SKIN boards

COMPLETE SKIN furniture boards are not just furniture components — they are a combination of aesthetics, innovation, and environmental care. Offering a wide range of designs and colors, the latest furniture components from Melaco give furniture manufacturers infinite design possibilities, while keeping in with global environmental trends. The materials and technologies we use ensure not only a perfect finish, but also high resistance to mechanical damage, moisture, and high temperature.

We highly encourage you to explore our collection of furniture boards and panels. Our experts will be happy to answer your questions and help you choose the right materials for your furniture. Contact our sales department:

Agata Sroczyńska

Sales Coordinator

+48 538 557 456

Contact

Do you have questions? Contact us.

We will be pleased to answer all questions about MELACO’s offer, terms of cooperation and orders. Write or call us.

Contact

Melaco sp. z o.o.

ul. Ciepielowska 9

67-100 Nowa Sól

Poland

SALES DEPARTMENT

Agata Sroczyńska

Sales Coordinator

SALES DEPARTMENT

Beata Prałat

Sales Specialist