This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Quality is in the details

The production process of furniture fronts requires high precision and attention to the smallest detail. These products must be adapted to the conditions prevailing in the room during use, depending on the intended use of the product, but also must offer many years of service life and resistance to damage. That is why our COMPLETE SKIN furniture forms are created in a very careful process with the use of modern production technologies.

First of all, in the production process we use MDF boards or chipboards from sustainable sources and marked with the FSC® certificate with reduced formaldehyde emission DIN EN 16516. We cover them with high-quality PVC, PET or PP foil for surface finishing and ABC and PVC edges to finish narrow planes. All in the selected colour or pattern.

The materials used and the production technology ensure a perfect finish of the forms, both on the surface and on the edges. It is also possible to apply different colours of the foil on the board and its edges – depending on the effect that the customer wants to achieve. We use polyurethane glue to apply the foil to the boards, ensuring maximum resistance to moisture and elevated temperatures.

You can read more about the process of creating furniture forms in the entry COMPLETE SKIN DOOR – How is the production process. If you want to learn more about wrapping narrow planes, we encourage you to read the entry: The technology of veneering narrow planes and panels in Melaco.

The advantage of COMPLETE SKIN forms is the possibility of finishing in almost any colour and pattern. Contact us to find out about the entire range of colours and receive a catalog with available finishes.

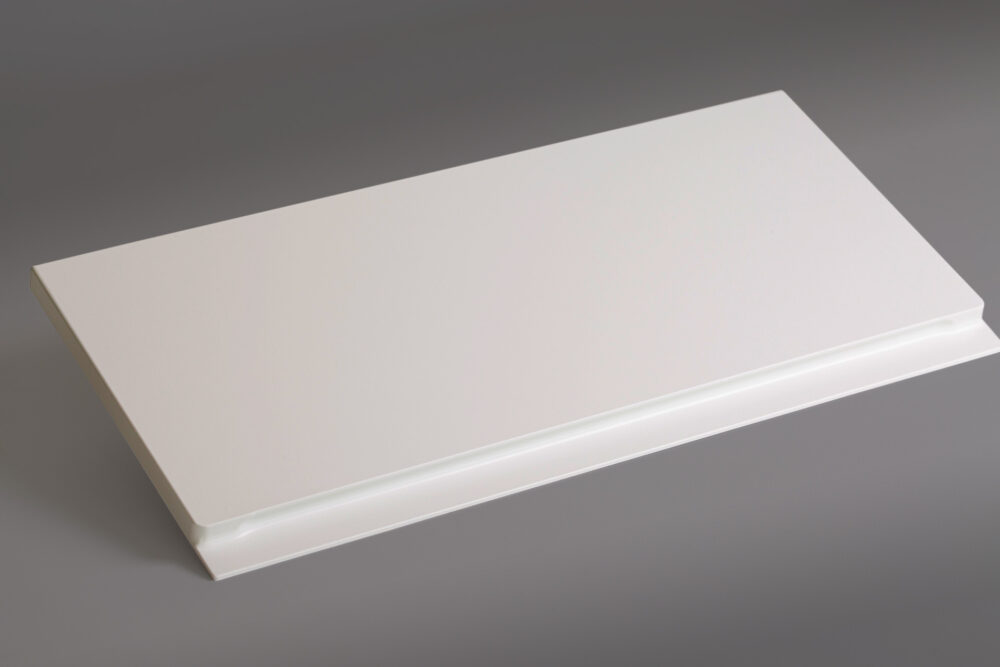

MAGIC GLOSS – high gloss and high resistance

For enthusiasts of elegant, high gloss effect, we have created the MAGIC GLOSS line, which impresses with its perfect surface and functionality. The above-average durability provides furniture fronts with a long service life, and the excellent quality of the polymer foil makes them resistant not only to moisture, but also to stains and UV rays. This means that MAGIC GLOSS fronts do not discolour over time, and keeping them clean is extremely easy. They are created on the basis of the vacuum pressing technology, during which the MDF board is covered with PVC or PET foil, secured with a protective foil. As standard, the left side is finished with a melamine layer.

PREMIER MATT – supermatt with regenerative ability

The PREMIER MATT finish is a solution for demanding customers, which we are able to apply on COMPLETE SKIN furniture boards and on fronts from the MELAFOL line. Provides an unusual mat structure, which is characterized by a low light reflectance (2-3) and exceptional smoothness. Like glossy panels, PREMIER MATT fronts are easy to clean. They are resistant to stains (1B) and scratches (1-1.5 N). What distinguishes this type of finish is the anti-fingerprint effect appreciated by users, as well as the ability to regenerate under the influence of heat.

The so-called ‘thermal healing’ effect allows you to independently remove small scratches from the surface of the plates caused by use. Just put a piece of cotton on the surface of the front and iron it – all scratches and scratches will disappear.

Learn more about Melaco matte fronts in the post: PREMIER MATT – a new standard of finishing furniture boards. If you are interested in available colours, please contact us and find out about the full range of colours for fronts in superman.

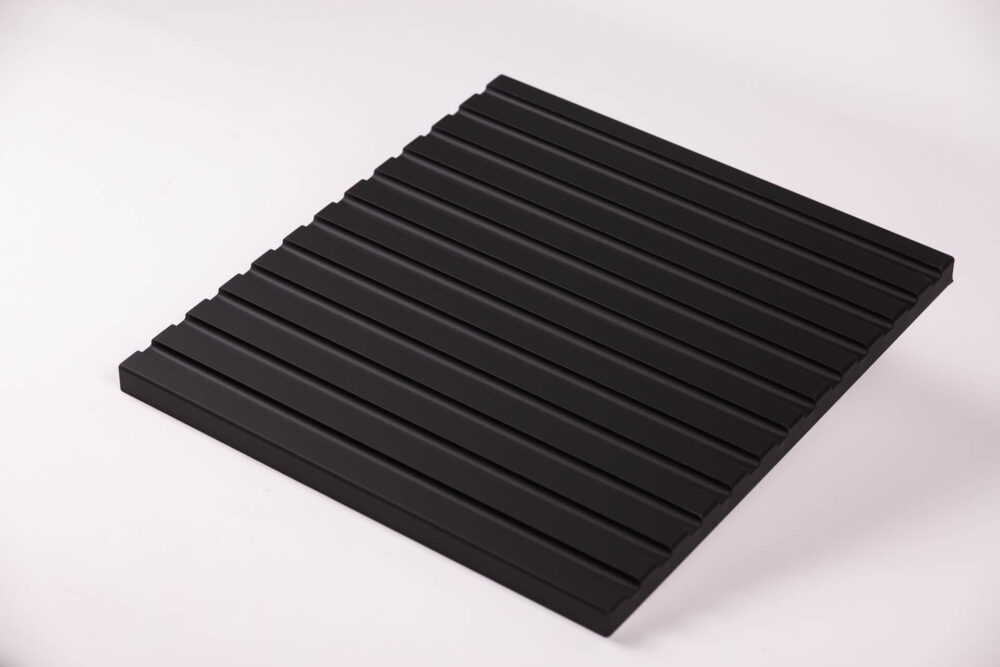

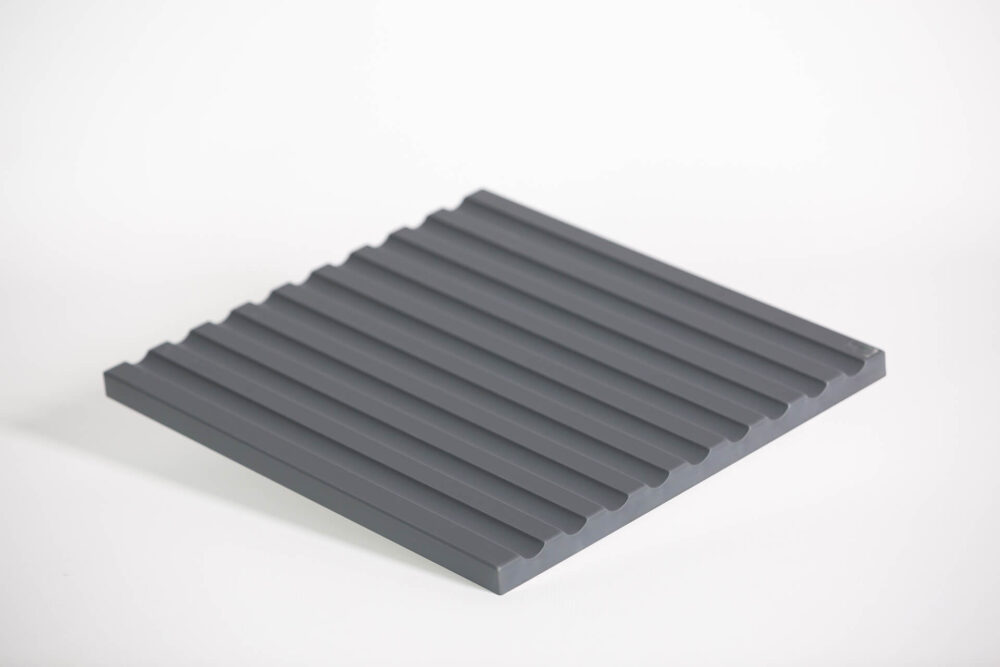

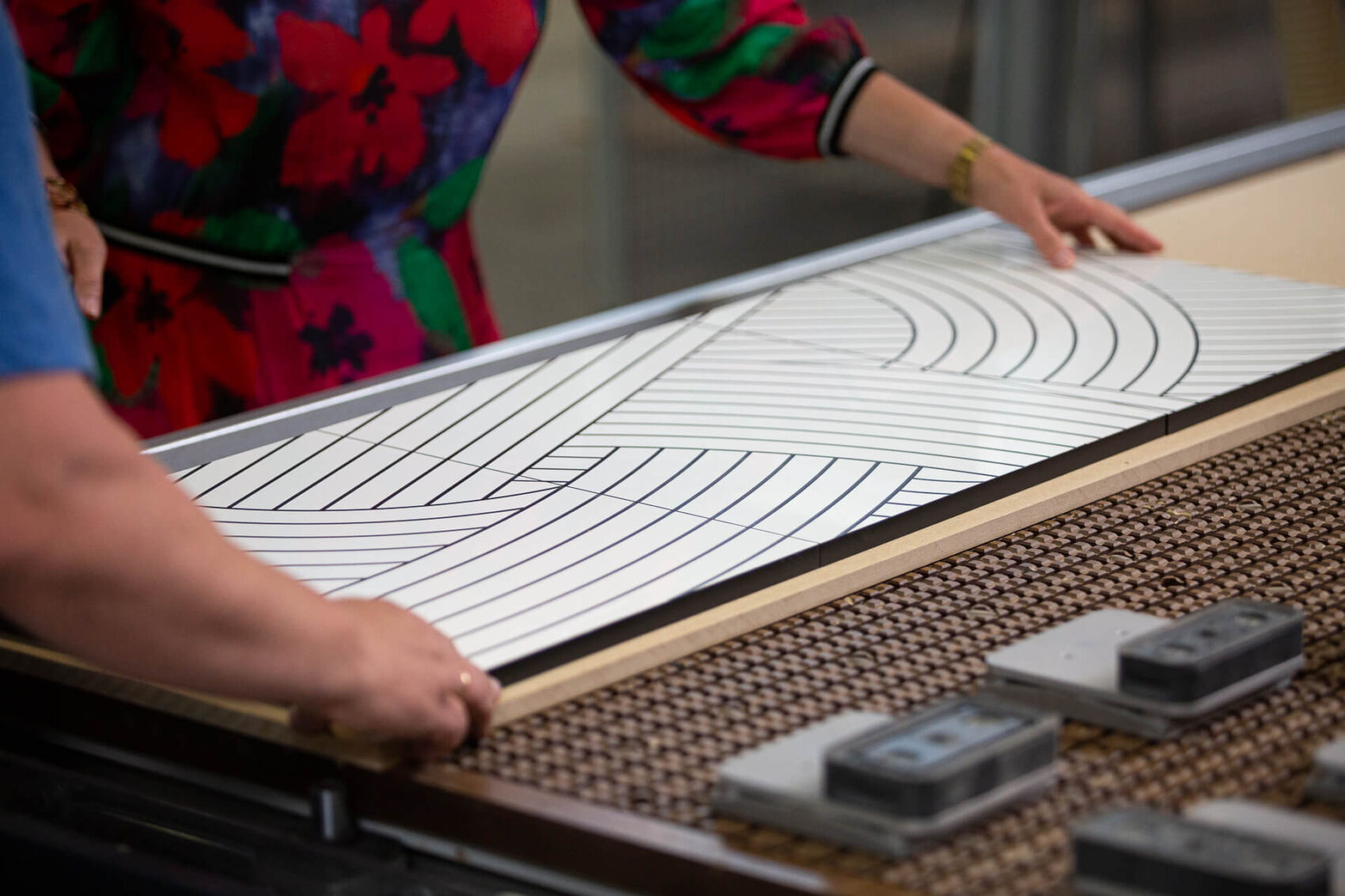

MICRO MILLING™ – precise cutters and two-colour effect

We offer producers of atypical furniture collections an effect based on precise CNC machining. MICRO MILLING™ consists in making cutters on the surface of a furniture board covered with a two-colour foil with a thickness of 200 μm to 300 μm. The outer layer is milled according to the design. Specialized copying units with real-time electronic thickness measurement and diamond cutters are used for processing. Processing in the MICRO MILLING™ technology is performed in the depth range of 50 μm-100 μm. In this process, we use specialized Alphacam software, which enables the import and processing into machine codes of very complex graphic designs made by our designers or received from the client.

In the MICRO MILLING™ technology, we make both minimalist lines and geometric patterns – to decorative ornaments. We are able to implement any project according to the client’s intention. The use of our high-quality films guarantees the fronts to maintain excellent strength parameters.

Find out more about this technology: MICRO MILLING™ – furniture fronts in a new version

MELAFOL – fronts with 3D effect

We also use milling processes in the MELAFOL line, where fronts with remarkable grooves are created – from modest, delicate to the deepest cutters characteristic of rustic furniture. We produce MELAFOL furniture fronts on the basis of 16-25 mm thick single-sided laminated MDF boards, which are covered with a polymer film in the vacuum pressing process.

The technologies used in this production line allowed us to create a truly unusual solution – fronts with a three-dimensional effect. We are able to apply any pattern to the surface of the board, according to the customer’s design, giving the furniture collection an unusual design.

This solution was appreciated by the jury of the Diamond of Furniture competition, awarding it a distinction in the plebiscite in 2021. Today, it is used by manufacturers of furniture fronts, whom we support in the implementation of their original ideas.

Find out more: Three-dimensional furniture fronts. Discover the possibilities of MELAFOL finishing

The MELAFOL milling technology also creates elegant handle-free fronts, which are an excellent alternative to handles and allow to unify the appearance of modern interiors.

Contact

Do you have questions? Contact us.

We will be pleased to answer all questions about MELACO’s offer, terms of cooperation and orders. Write or call us.

Contact

Melaco sp. z o.o.

ul. Ciepielowska 9

67-100 Nowa Sól

Poland

SALES DEPARTMENT

Agata Sroczyńska

Sales Coordinator

SALES DEPARTMENT

Beata Prałat

Sales Specialist