This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Vacuum technology in the production of furniture elements

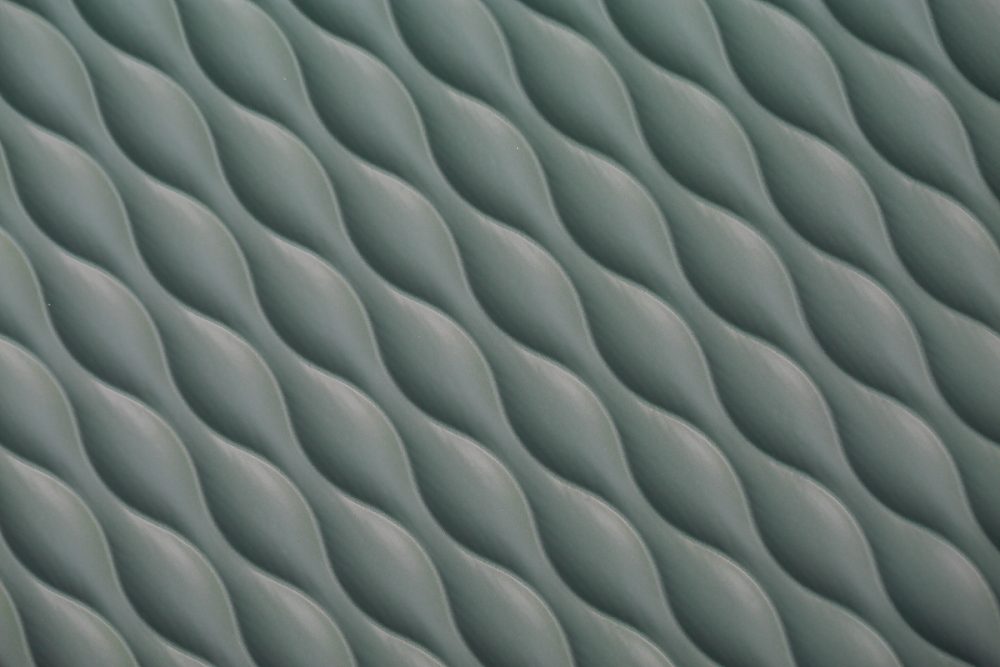

The use of this innovative technology is possible thanks to a modern membrane-vacuum press, which we use to cover furniture elements with thermoplastic foil. It precisely covers the component in three planes. We then obtain a unique and extremely aesthetic 3D effect.

How do we provide our products with such perfect workmanship? This is largely due to our experienced operators who know very well how to work with any type of foil. Also with such demanding foils as PREMIER MATT.

‘You have to use the appropriate parameters for each foil and enter them into the press each time. The foil should be properly heated, but it should not be overheated, so the proper setting of the device is crucial. It is also very important to maintain cleanliness and even, precise arrangement of elements on the press table, which ensures that ideal pressing parameters are obtained on the entire surface of the product’– says Przemysław Kopaczewski, press operator at Melaco.

Vacuum technology, in addition to the 3D effect and high aesthetic values, also ensures high surface durability of the furniture elements produced. They are resistant to moisture and elevated temperatures. Our products are subjected to continuous trials in the form of an increasing thermal test, which is why our clients have a guarantee that the foil will not peel off when the furniture is transported in the container to the recipient, where the temperature sometimes exceeds 60°C. Moreover, the parameters of the fronts manufactured in Melaco ensure safe, long-term use by the end customer.

Also worth mentioning is the fact that all minor scratches can be easily ‘healed’. These are important features of furniture fronts in the innovative PREMIER MAT finish.

PREMIER MATT – when supermatt is not enough

We have achieved deep matt in the PREMIER MATT finish and the durability of the foil thanks to the innovative PST (Physical Surface Treatment) technology. It meets the expectations of the most demanding customers. The PREMIER MATT finish is distinguished by aesthetic workmanship, fashionable colors and above-average durability, characteristic of premium class products.

Its hallmark is its unusual matt structure with a low light reflectance (2-3). The surface covered with the PM foil is easy to clean and extremely smooth. An important feature from the point of view of users is also the anti-fingerprint effect, which protects the surface against fingerprints, as well as resistance to staining, coloring and scratching.

Also read: PREMIER MATT – a new standard of panel finishing furniture

Any damage on the surface of the front? No need to worry. All you need is an iron and a piece of cotton cloth to get rid of them.

How to ‘heal’ a PREMIER MATT front?

Minor scratches and mechanical damage resulting from the use of the furniture can be easily ‘healed’ at home. There is no need to return the front for renovation or use the help of a specialist.

The PREMIER MATT finish has this property which allows the surface to be restored to its original state under the influence of increased temperature. For this purpose, the damaged fragment should be ironed with a cotton cloth on top of it. After a while, all scratches will disappear, and the furniture can be used by the household members for years to come, while maintaining its elegant look.

It is also important from the point of view of furniture manufacturers, because it allows to minimize the lack of production due to minor damage in the form of scratches at the stage of the production process.

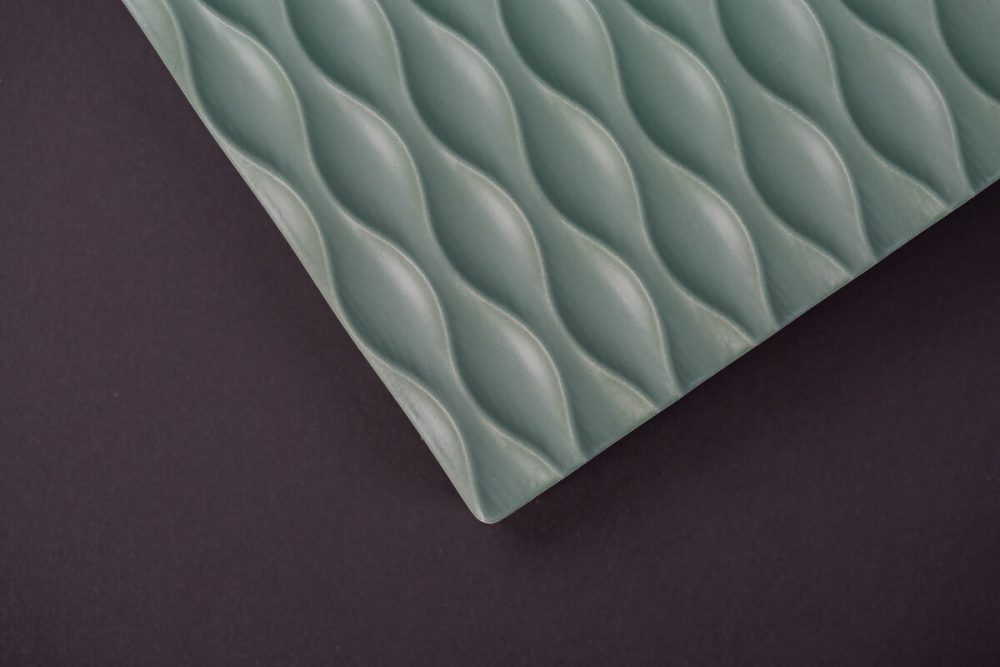

Amazing milling cutters – MELAFOL fronts

We also successfully use the membrane-vacuum technology to produce MELAFOL fronts, which are characterized by an atypical surface structure. Thanks to the milling processes, we can give the fronts any finish, helping to create furniture with unique character.

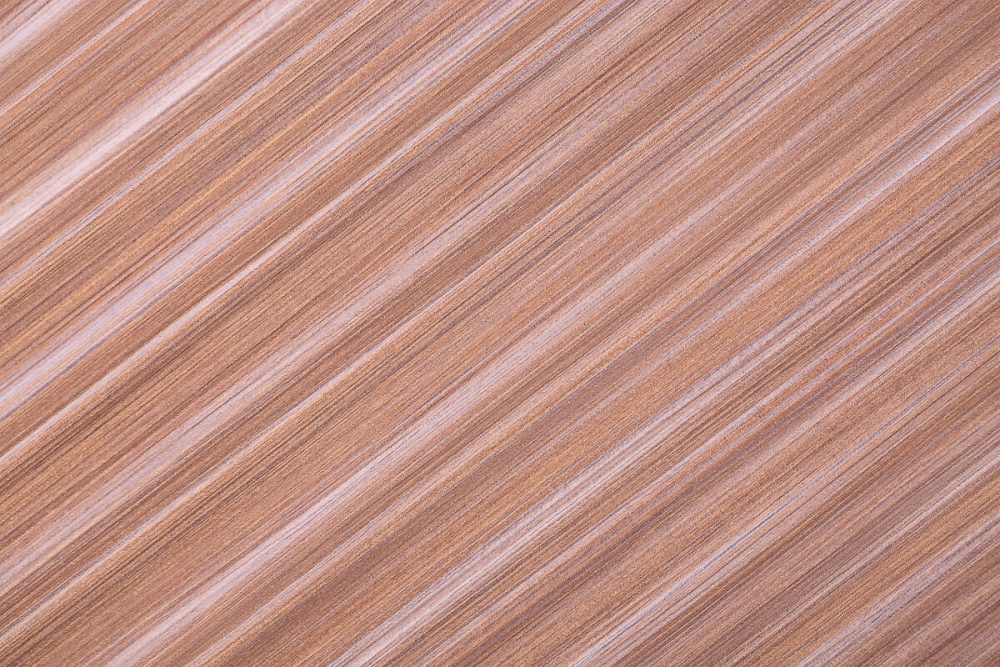

MELAFOL furniture fronts are available in all colors and foil designs available from MELACO and the suppliers we work with. We offer dozens of patterns and milling methods. We implement projects according to the parameters suggested by the client, but we also offer our own ready-made projects.

Contact

Do you have questions? Contact us.

We will be pleased to answer all questions about MELACO’s offer, terms of cooperation and orders. Write or call us.

Contact

Melaco sp. z o.o.

ul. Ciepielowska 9

67-100 Nowa Sól

Poland

SALES DEPARTMENT

Agata Sroczyńska

Sales Coordinator

SALES DEPARTMENT

Beata Prałat

Sales Specialist